Бетонный завод объединяет хранение, транспортировку, взвешивание и смешивание в единую систему для производства высококачественного бетона. Эти установки дозируют сырье по весу для поддержания однородности смеси и достижения производственных показателей по различным видам бетона.

Знание компонентов бетонного завода помогает повысить точность, сократить количество отходов и обеспечить воспроизводимые результаты на любой строительной площадке. Каждый бетонный завод В зависимости от потребностей производства и уровня автоматизации используются различные схемы, но все они опираются на одни и те же основные детали.

Бетонные заводы включают в себя стационарные, мобильные бетонные заводы, заводы с мокрой или сухой смесью. Эти установки различаются по способу смешивания, хранения и транспортировки бетона, но все они следуют одним и тем же принципам дозирования.

Если вы поставляете готовую смесь, заливаете сборный бетон или инвестируете в бетонный завод для выполнения индивидуальных работ, понимание принципов работы каждого устройства повышает эффективность, поддерживает контроль качества и обеспечивает долгосрочную производительность.

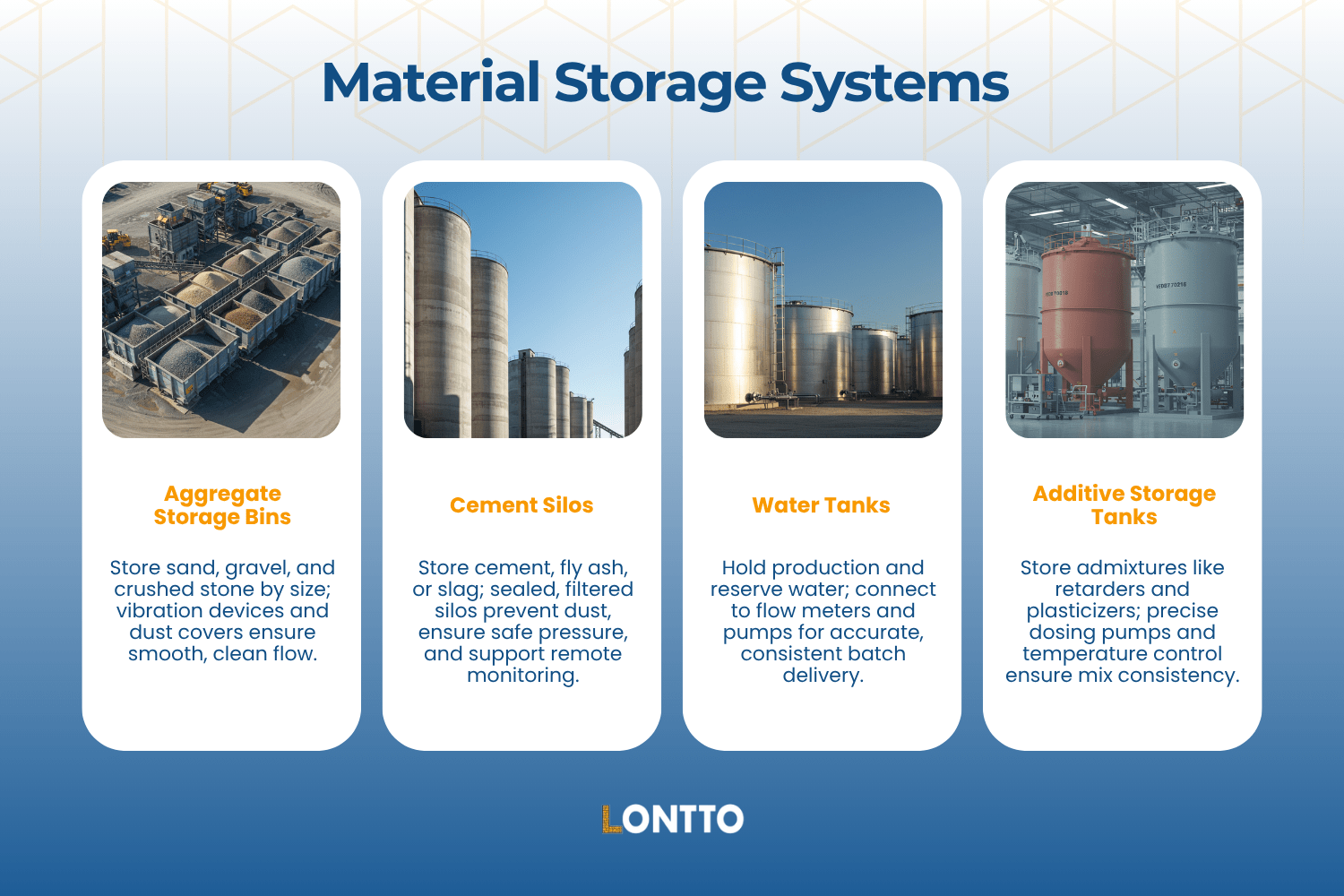

Системы хранения материалов

Для поддержания стабильного производства все компоненты бетонных заводов зависят от специального хранилища материалов. В бункерах, силосах и резервуарах хранятся заполнители, цемент, вода и добавки, необходимые для каждой партии бетона.

Эти компоненты бетонных заводов защищают материалы от влаги, предотвращают их загрязнение и обеспечивают точную выгрузку. Планировка зависит от типа завода, но хранение всегда влияет на поток, время простоя и эффективность процесса дозирования.

Бункеры для хранения щебня

В бункерах для хранения песка, гравия и щебня хранятся материалы, разделенные по типу и размеру. В большинстве компонентов бетонных заводов используется от 3 до 6 отсеков для изолированного хранения материалов во время загрузки и выгрузки.

В бункеры часто устанавливают вибрационные устройства для предотвращения образования мостов и проблем с потоком. В некоторые системы добавляются датчики влажности для регулировки подачи воды в процессе дозирования, а большинство систем оснащены пылезащитными кожухами для контроля частиц, находящихся в воздухе, и поддержания чистоты заполнителя в уличных условиях.

Силосы для цемента

Силосы для цемента хранят порошок материалы, такие как цемент, летучая зола, шлак и кварцевого дыма в герметичных условиях. Большинство силосов имеют вертикальную конструкцию, крепятся болтами, свариваются или строятся как горизонтальные резервуары для мобильных установок.

Вместимость бункеров варьируется от 50 до более чем 1 000 тонн, при этом размер зависит от объема смеси и частоты пополнения. Каждый силос оснащен клапаном сброса давления для предотвращения перегрузки и повреждения конструкции при пневматическом заполнении.

Для борьбы с пылью используются встроенные фильтры или внешние системы пылеулавливания. Разгрузка осуществляется с помощью шнекового питателя, который дозирует материал в бункер весов постоянным потоком. Современные силосы поддерживают дистанционный контроль уровня, что снижает необходимость в ручном контроле и улучшает планирование пополнения запасов на крупнотоннажных бетонных заводах.

Резервуары для воды

Водяной бак бетонных заводов должен вмещать достаточное количество воды для ежедневного производства, а также аварийный запас. При определении размера учитывается объем партии, планируемое время простоя и количество одновременных циклов смешивания.

Резервуары подключаются к расходомерам, которые измеряют точный объем для каждого цикла смешивания, а встроенные насосы регулируют давление подачи. Неразмерные резервуары могут ограничивать скорость пополнения и задерживать дозирование, особенно в высокопроизводительных дозирующих установках.

Некоторые резервуары изолированы для контроля температуры, а в других используются сигнализаторы уровня для предотвращения работы насоса всухую. Размещение резервуаров тщательно продумано с учетом доступа к дозаправке, возможности самотечной подачи и частоты очистки.

Емкости для хранения присадок

В резервуарах для добавок хранятся такие химические вещества, как замедлители, ускорители и пластификаторы, каждый из которых находится в отдельных отсеках для предотвращения перекрестного загрязнения. Объем резервуара зависит от дозировки, срока годности добавок и частоты смешивания.

Каждый резервуар подключается к специальному дозирующему насосу, который тщательно дозирует добавки в смесь с точностью до миллилитра. Калибровка насоса предотвращает передозировку, которая может нарушить время схватывания или снизить прочность бетона.

Для поддержания рабочих характеристик добавок, чувствительных к температуре, могут потребоваться резервуары с рубашкой или кожухи, чтобы сохранить их производительность при сезонных изменениях. Утечки или проникновение воздуха в эти системы могут повлиять на время замеса и стабильность химических веществ в нескольких компонентах бетонного завода.

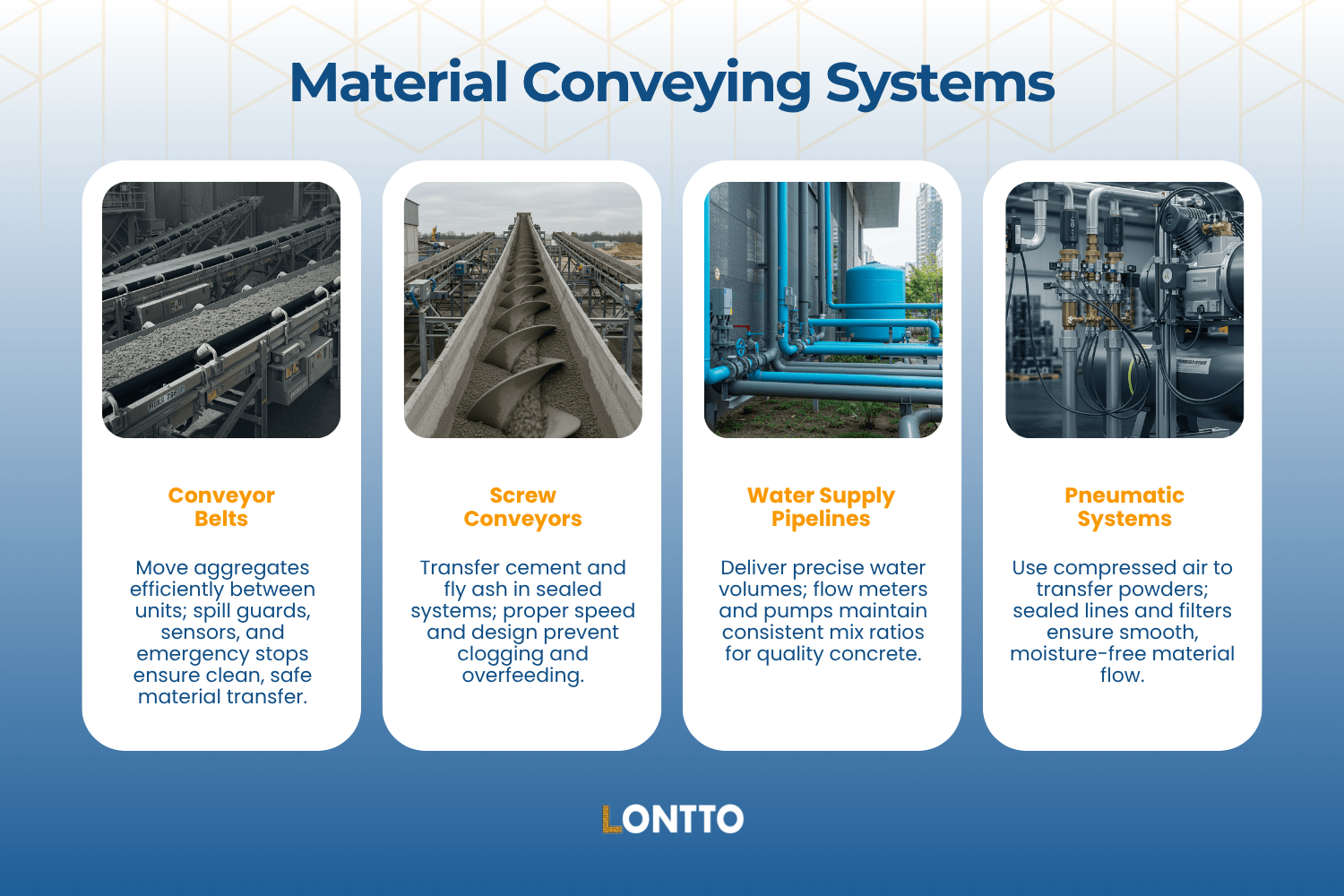

Системы транспортировки материалов

Компоненты бетонных заводов включают системы, которые перемещают материалы между складами, весами и смесителями. Такие системы, как конвейеры, шнековые транспортеры и пневматические системы, перемещают цемент, заполнитель и добавки по герметичным каналам, чтобы сократить потери и ускорить циклы дозирования.

Системы этих заводов должны быть точно синхронизированы, чтобы предотвратить такие проблемы, как переполнение, задержка материала или задержки в подключенных системах дозирования бетона.

Конвейерные ленты

Конвейерные ленты перемещают заполнитель из хранилища в весовые устройства непрерывным потоком с минимальными потерями материала. В большинстве систем используются наклонные или горизонтальные ленты, размер которых зависит от ширины ленты, производительности и мощности двигателя.

Приводные узлы должны соответствовать скорости загрузки, чтобы избежать скачкообразной подачи, которая нарушает последующий процесс дозирования. Защитные экраны и бортики снижают количество пыли и утечек в местах перегрузки, особенно на бетонных заводах с приподнятой планировкой.

В каждой ленте предусмотрена схема аварийного останова, связанная с логикой управления, для остановки работы при застревании, превышении скорости или смещении ленты.

Винтовые конвейеры

Шнековые транспортеры перемещают порошкообразные материалы, такие как цемент и летучая зола, из силосов в бункеры весов. Их закрытая конструкция защищает от влаги и ветра во время дозирования.

Скорость и шаг шнека должны соответствовать скорости потока, чтобы предотвратить образование мостов или перекорм в бетономешалку. В крупных установках периодического действия несколько шнеков могут работать параллельно для обеспечения более высокой производительности без сегрегации материала.

Поломки двигателей и подшипников - обычное явление при работе в условиях высокого цикла, поэтому компоненты привода должны быть подобраны с учетом времени работы и тепловой нагрузки в системах дозирования бетона.

Трубопроводы водоснабжения

Вода поступает в системы дозирования бетона по трубопроводам, оснащенным расходомерами и регулирующими клапанами. Насосы регулируют скорость подачи в зависимости от соотношения компонентов смеси, а точность дозирования зависит от размера партии и влажности заполнителя.

Неправильная калибровка увеличивает разброс соотношения воды и цемента, что снижает качество бетона. Схема трубопровода должна минимизировать мертвые зоны, где изменения температуры или давления влияют на характеристики смеси во время ее передачи в бетоносмеситель.

Пневматические системы

Пневматические системы используют давление сжатого воздуха для перемещения цемента и летучей золы из силосов в весовой бункер. В этих системах используются герметичные трубы, регулирующие клапаны и центральный компрессор для поддержания потока порошка.

Когда давление падает, подача прекращается. Это замедляет подачу следующей партии и задерживает работу миксера. На большинстве бетонных заводов устанавливаются фильтры для удаления влаги из линии до того, как она засорит поток.

Весовые системы

Точность каждого замеса начинается со взвешивания. Цемент, заполнитель, вода и химические добавки загружаются на отдельные весы, чтобы соблюсти точное соотношение и избежать сбоев в работе смеси в дальнейшем.

Небольшие изменения в весе могут изменить прочность, расход или время схватывания бетона. Именно поэтому на большинстве стационарных заводов используются автоматические системы, которые приостанавливают подачу смеси, когда ее количество выходит за пределы допустимого. Ручные установки полагаются на оператора, который должен уловить смещение до того, как смесь будет выброшена за пределы нормы.

Влажность заполнителя также изменяет количество необходимой воды. Если ее не отрегулировать, соотношение воды и цемента нарушится. Некоторые заводы устанавливают датчики влажности до того, как материал попадает на весы, что помогает системе корректировать количество воды без изменения остальной конструкции бетонной смеси.

Смесительный узел

Смесительный узел является одним из основные компоненты бетонных заводов в любой бетоносмесительной установке. В нем цемент, вода и заполнители смешиваются в контролируемую бетонную смесь. Эта стадия определяет качество бетона и влияет на то, насколько эффективно он будет продвигаться по остальным этапам процесса замеса.

Типы смесителей

Все смесители оснащены износостойкими вкладышами, сменными лопастями и регулируемыми разгрузочными затворами для защиты движущихся частей и обеспечения стабильной подачи бетона на выходе.

- Двойной вал: Высокоинтенсивное перемешивание для непрерывного производства бетона на центральных бетоносмесительных установках. Распространен в конструкциях стационарных бетонных заводов, обрабатывающих большие объемы бетона.

- Планетарий: Поставляет однородные партии для сборного бетона и специальных видов бетона, требующих жестких допусков при проектировании бетонной смеси.

- Миксеры для кастрюль: Подходит для небольших бетонных заводов, где важны компактность оборудования и быстрые циклы очистки.

- Смесители с наклонным барабаном: Часто встречается в портативных бетонных системах и базовых проектах с порционным бетоном, требующих простых операций на заводе.

- Смесители с одним валом: Гибкость при изготовлении нестандартных смесей, обычно используется производителями бетона, поставляющими переменные объемы готовой бетонной смеси.

Система разгрузки

Система выгрузки контролирует выход свежего бетона из смесителя и его перемещение в транспортные узлы. Большинство компонентов бетонных заводов зависят от этого этапа, чтобы обеспечить непрерывность производства.

Разгрузочные затворы располагаются под смесителем и открываются вручную, пневматически или гидравлически, в зависимости от типа установки. Пневматические системы распространены в стационарных установках, а гидравлическая разгрузка подходит для централизованного смешивания, где важны скорость и контроль.

Установка должна соответствовать способу доставки. Готовая бетонная смесь поступает непосредственно в транзитные миксеры, в то время как для сборных бетонных форм часто используются бункеры или конвейеры. Плохое управление затворами может привести к разливу, разделению смеси или задержке погрузки.

Система управления

Система управления управляет всем процессом дозирования и смешивания, от взвешивания ингредиентов до конечной выгрузки. На современных заводах она работает через интерфейс ПЛК или SCADA, связанный с программным обеспечением для дозирования, которое автоматизирует последовательность действий, контроль соотношения и обнаружение ошибок.

Для каждого стационарного бетонного завода используется индивидуальная схема диспетчерской в зависимости от размера завода и эксплуатационных потребностей. Компоненты бетонных заводов часто включают панели с сенсорным экраном, аварийные блокировки и дистанционное управление. Эти функции упрощают работу завода и позволяют бригадам производить высококачественный бетон с меньшим количеством ручных настроек.

Программное обеспечение отслеживает циклы смешивания, вес ингредиентов и коррекцию влажности в режиме реального времени. Функции безопасности, такие как сигнализация и блокировка, защищают движущиеся части и помогают сохранить качество бетона даже под давлением.

Большинство систем регистрируют данные о каждой произведенной партии бетона, позволяя производителям бетона проверять консистенцию смеси и обеспечивать прослеживаемость записей для готовых бетонных смесей или сборного бетона.

Электрические и энергетические системы

Для бесперебойной работы компонентов бетонного завода требуется постоянное электропитание. Большинство стационарных бетонных заводов получают электроэнергию непосредственно из сети, но небольшие бетонные заводы или удаленные рабочие места могут включать в себя генератор в качестве резервного источника.

Двигатели, редукторы и частотные приводы управляют движением смесителей, насосов и конвейеров. Это ключевые компоненты, обеспечивающие плавность и безопасность процесса дозирования и смешивания. Электрические панели содержат автоматические выключатели, реле и защиту от перегрузки, чтобы сократить время простоя и защитить движущиеся части.

Гидравлические и пневматические цепи также обеспечивают выполнение вспомогательных задач на современных заводах, таких как управление воротами и подъем оборудования. Без надежного электрооборудования становится сложнее производить высококачественный бетон всех типов.

Вспомогательные системы

Вспомогательные системы поддерживают компоненты бетонного завода, повышая производительность, стабильность и безопасность. Они помогают заводу бесперебойно работать в условиях сезонных смен, циклов большой производительности и необходимости постоянного технического обслуживания.

Системы пылеулавливания

Пыль из цементных силосов, бункеров для заполнителей и зон смешивания может снизить качество бетона и создать опасность для воздуха. Централизованные системы сбора пыли используют рукавные или патронные фильтры для улавливания частиц воздуха до их распространения.

Эти устройства часто устанавливаются рядом с конвейерами и смесителями на стационарных заводах или централизованных установках. Удаляя мелкую цементную пыль, они защищают как оборудование, так и конструкцию бетонной смеси.

Нагревательное/размольное оборудование

Контроль температуры помогает производить высококачественный бетон в жарких или холодных условиях. Небольшие бетонные заводы могут использовать резервуары с подогретой водой зимой, в то время как более крупные бетоносмесительные установки включают промышленные чиллеры для охлаждения заполнителя или водопроводных линий летом.

Контроль температуры смеси помогает поддерживать производительность дозирования и смешивания и обеспечивает стабильное качество бетона при каждой загрузке.

Вибраторы и приспособления для обтекания

Застревание материала в бункерах, воронках или питателях может привести к задержке процесса дозирования и снижению производительности установки. Пневматические или электрические вибраторы устанавливаются для разрыхления застрявшего материала и поддержания стабильного потока. Эти движущиеся части помогают эффективно подавать бетон, особенно при больших объемах работ.

Особенности безопасности и обслуживания

Современные заводы оснащены лестницами для обслуживания, ограждениями и платформами для обеспечения безопасности работы. Системы смазки достигают движущихся компонентов, таких как смесители и конвейеры, сокращая время простоя и износ. Удобные места доступа упрощают обслуживание, защищают высококачественные компоненты и продлевают срок службы оборудования.

Часто задаваемые вопросы о компонентах бетонных заводов

Как влажность заполнителя влияет на качество бетона?

Избыток воды из влажных агрегатов изменяет водоцементное отношение, Это ослабляет смесь и влияет на консистенцию. Датчики влажности позволяют системе регулировать подачу воды в режиме реального времени, сохраняя прочность и конечный результат в разных партиях.

Как контроль пыли и температуры повышает безопасность предприятия?

Системы пылеулавливания предотвращают попадание в воздух частиц, засоряющих оборудование и представляющих опасность для здоровья, а системы контроля температуры предотвращают замерзание или перегрев, которые могут повредить насосы, клапаны или электрические блоки.

Какое техническое обслуживание обеспечивает бесперебойную работу бетонных заводов?

Ежедневная смазка, проверка ремней, калибровка датчиков и осмотр смесителей сокращают незапланированные простои и продлевают срок службы оборудования. Соблюдение графика технического обслуживания помогает поддерживать стабильность производства и высокую рентабельность инвестиций.

Вернуться к началу: Компоненты бетонных заводов | Ключевые компоненты бетонных заводов

Меня зовут Чао Чжан, я работаю в сфере производства кирпича уже более 10 лет. У меня есть глубокое понимание и исследования различных моделей машин для производства блоков, особенно автоматических машин для производства кирпича, машин для производства бетонных блоков, машин для производства блоков из прессованной земли, машин для производства глиняного кирпича, машин для производства цементного кирпича. У меня есть особое понимание этой отрасли. Я могу помочь своим клиентам выбрать подходящую машину для производства кирпича и помочь им в проектировании и строительстве завода по производству кирпича. Если вы хотите узнать все о машинах для производства кирпича, пожалуйста, свяжитесь со мной. Я буду рад помочь вам.