India's construction industries are growing rapidly, and the demand for high-quality concrete blocks is high. Whether you're setting up a new manufacturing plant or upgrading your existing block production line, or working in residential, commercial or infrastructure projects, choosing the right machine from reliable block making machine manufacturers is a big part of your success.

This guide covers what to look for in block machine manufacturers and ranks the top 10 concrete block making machine manufacturers in India based on machinery quality, automation levels, after-sales service and customer feedback. By the end, you'll know which manufacturer offers the best quality machines for your specific production needs.

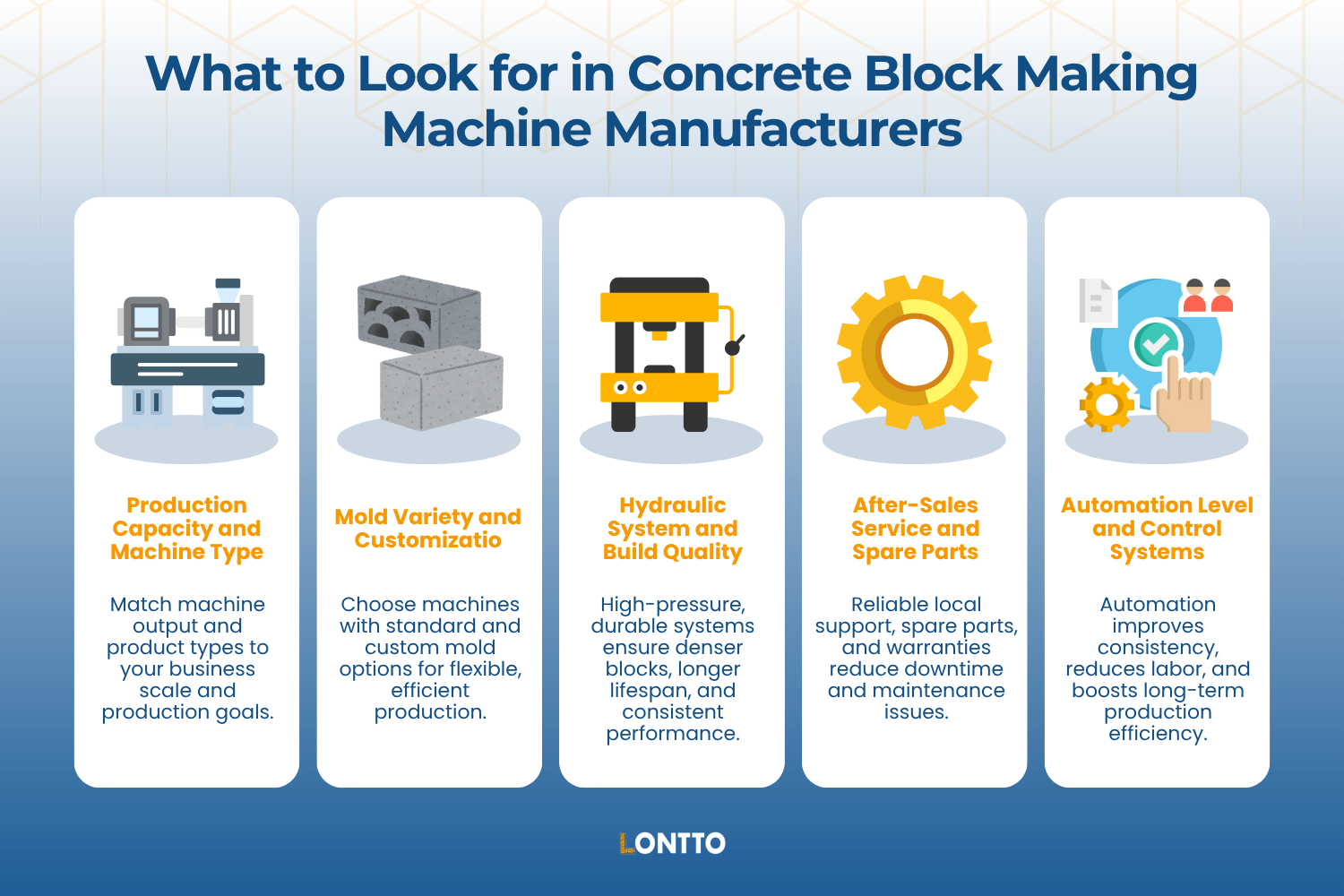

What to Look for in Concrete Block Making Machine Manufacturers in India

Selecting the right block machine manufacturer determines production efficiency, maintenance costs, and long-term profitability. Focus on these five factors:

- Production Capacity and Machine Type: Match output (blocks per hour/day) to your business scale. Verify the machine can produce your target products: hollow blocks, solid blocks, paver blocks, fly ash bricks or multiple types.

- Mold Variety and Customization: Ensure manufacturer offers standard sizes plus custom mold design capability. Quick mold changeover systems reduce downtime between production runs.

- Hydraulic System and Build Quality: High-pressure systems (15 to 25 MPa) produce denser, stronger blocks with better compressive strength. Robust frame construction and wear-resistant components extend machine lifespan. Consistent vibration systems eliminate air pockets and ensure uniform block density.

- After-Sales Service and Spare Parts: Local service centers and technical support minimize downtime when repairs are needed. Readily available spare parts keep production running. Standard warranties should cover major components with clear claim processes.

- Automation Level and Control Systems: Automation reduces labor and improves consistency. Manual machines suit small operations, semi-automatic models balance cost and efficiency, while fully automatic systems use PLC controls for precision. Higher automation requires more investment but delivers better long-term returns through reduced labor costs and improved block production efficiency.

Top 10 Concrete Block Making Machine Manufacturers in India

1. Máquina de bloques Lontto

Lontto operates three manufacturing plants across 126,000 square meters and produces around 200 block making machines and 7,000 construction machines annually!

The company offers fully automatic, semi-automatic and manual type machines with production capacity ranging from 720 to 28,800 blocks per day. There's something for every need here.

Lontto integrates components from Siemens, Schneider, Panasonic and Omron into their machinery. All machines are CE and ISO 9001 certified with a 1-year warranty. With every order, you'll get free installation, training, one set of molds and door-to-door shipping with marine insurance coverage.

With established delivery routes to Asia and proven experience supplying construction machinery across developing markets, Lontto understands the demands of construction industries in India and offers competitive pricing for volume orders.

| Pros | Contras |

|---|---|

| ✅ High-manganese (16Mn) steel frame construction increases durability and extends machine lifespan under continuous operation. | ❌ Warranty excludes shipping costs for replacement parts, which can add expense for international customers. |

| ✅ Advanced vibration motor systems ensure uniform compaction and consistent block density across all production runs. | |

| ✅ Delivery times of 10 to 40 days depending on region, with customs clearance support and local agent partnerships in multiple countries. |

2. Industrias Revomac

Revomac Industries, established in 2010 and based in Ahmedabad, Gujarat, specializes in manufacturing concrete block machines using German technology and high-quality parts from premium suppliers like Siemens and ABB Rexroth.

Their product line includes fully automatic, semi-automatic and hydraulic brick making machines with production capacity ranging from 1,260 to 28,800 blocks per shift. This concrete block making machine manufacturer in India produces solid blocks, hollow block production, paver blocks, fly ash bricks and kerb stones with customizable mold systems.

Revomac's solid block making machines produce concrete blocks meeting BIS 2185.1.2005 standards, with compressive strength of 3.5 to 7.5 MPa and water absorption under 6%.

The manufacturer provides turnkey project solutions from 10,000 to 120,000 pieces per day, including auto batching plants and autoclave systems for complete block production lines.

| Pros | Contras |

|---|---|

| ✅ Local manufacturing in Ahmedabad ensures faster delivery, lower shipping costs and easier access to after-sales service for Indian customers. | ❌ Established in 2010, making them a relatively newer player compared to manufacturers with decades of industry experience. |

| ✅ Vibro + Hydro technology combines vibration and hydraulic compaction for superior block density and consistent quality across batches. | |

| ✅ Quick-change mold system enables switching between multiple block types without extended downtime or complex retooling. |

3. Everon Impex

Everon Impex, established in 2011 and ISO 9001:2015 certified, operates from Coimbatore, Tamil Nadu, with four production units specializing in construction machinery. The company manufactures hydraulic concrete block making machines, egg-laying mobile block machines and stationary block production systems with capacity ranging from 500 to 2,000 blocks per shift.

Their hydraulic systems operate at 140 kg/cm³ pressure with triple vibrator configurations (2 HP mould vibrator, 1.5 HP ram vibrator) for consistent block density. Models include semi-automatic and fully automatic machines producing hollow block units, solid blocks, fly ash bricks, paver blocks and interlocking blocks.

Everon Impex uses mild steel construction with chrome-plated molds and integrated quality control at every production stage. They're a concrete block making machine manufacturer in India, but they also supply South Africa, West Africa, North Africa and South America with very competitive prices depending on automation level.

| Pros | Contras |

|---|---|

| ✅ Egg-laying mobile design allows on-wheels operation, enabling direct block placement on concrete floors without pallets for faster production cycles. | ❌ Smaller scale operation may limit spare parts inventory and after-sales support network compared to industry leaders. |

| ✅ One-touch operating system with auto pressure control and hi-tech panels simplifies operation for workers with minimal technical training. | |

| ✅ Local South India manufacturing base offers shorter delivery times and lower logistics costs for customers in India. |

4. Columbia Machine Engineering

Columbia Machine Engineering is a concrete block making machine manufacturer in India (Mumbai, to be specific) with over 87 years of global concrete machinery experience.

The company manufactures SPM20, SPM26 and SPM30 models using patented Constant Vertical mould Vibration Technology (CVT) that delivers even compaction and 20% lower cement consumption compared to conventional machines.

Production capacity ranges from 50,000 hollow blocks to 300,000 fly ash bricks per day across different models. Columbia's machines produce hollow blocks, solid blocks, paver blocks, segmental retaining wall (SRW) blocks, kerbstones and fly ash bricks, which meet stringent dimensional accuracy requirements for commercial projects like ports, highways and heavy-duty applications.

| Pros | Contras |

|---|---|

| ✅ Patented CVT technology reduces mold wear and provides industry-leading product height control regardless of production pallet thickness variations. | ❌ Premium pricing compared to other domestic manufacturers may create higher initial capital requirements for small to mid-sized operations. |

| ✅ Over 200 SPM20 machines operating across India for 15+ years demonstrate proven reliability and established service support network nationwide. | |

| ✅ Strong integration with parent company's global R&D delivers continuous technology upgrades and access to international concrete product innovations. |

5. Parijatha Machinery

Sri Parijatha Machinery Works Pvt. Ltd., started in 1990 in Bangalore, operates three state-of-the-art manufacturing facilities with over 35 years of experience in precast concrete machinery.

The company produces BlockMaster (fully automatic) and BlockStar (semi-automatic) series with production capacity ranging from 900 to 2,000 cycles per 8-hour shift. Their APM-216 hermetic press is the most produced machine of its kind globally, allowing small manufacturers to gain access to cutting-edge technology at affordable prices.

Their flagship BM1000 features a specially designed hydraulic power pack with modular manifold blocks, multi-stage automated speed controls and intense vibration systems for superior product quality with minimum raw material costs.

Parijatha's machines use tubular heavy-duty frame construction, CNC machining centers and EU-standard PLC control systems with HMI interfaces. They produce concrete masonry blocks, paver blocks, fly ash bricks, kerbstones, terrazzo tiles, and wet-cast products (being the only manufacturer of wet press tech in the country).

| Pros | Contras |

|---|---|

| ✅ DUPLEX hopper feed system provides measured material distribution into mould cavities, improving product thickness consistency and strength uniformity. | ❌ Smaller brand recognition compared to international manufacturers may limit perceived quality in premium construction projects. |

| ✅ Complete in-house design and manufacturing using CNC plasma cutting and modern welding technologies gives full quality control and faster after-sales service response. | |

| ✅ Sole manufacturer of wet press technology in India, offering unique capabilities for producing terrazzo tiles, decorative slabs and high-density paving products. |

6. Apollo Zenith

Apollo Zenith Concrete Technologies Pvt. Ltd., is a joint venture between Apollo Inffratech and German manufacturer Zenith Maschinenfabrik. This partnership uniquely positions Apollo Zenith as the sole provider of authentic German-engineered Zenith technology manufactured in India at competitive local pricing.

Their product range includes ZN400, ZN600, ZN900, ZN1000 and Zenith 1500 models featuring Siemens frequency control technology that reduces power consumption by 20 to 40% compared to traditional motors.

Production capacity ranges from 500 to 1,500 blocks per hour, depending on model selection. The machines incorporate non-pallet block producing technology pioneered by Zenith over six decades, getting rid of pallet costs entirely.

| Pros | Contras |

|---|---|

| ✅ Direct German R&D technology provides continuous innovation and access to six decades of non-pallet block machine expertise. | ❌ Higher initial investment compared to domestic competitors may create entry barriers for small-scale manufacturers. |

| ✅ Integrated structure of vibrating and molding platform prevents mechanical accidents caused by operational mistakes through simplified, fail-safe design. | |

| ✅ Part of Apollo Inffratech Group ecosystem offering complete concrete solutions including batching plants, mixers and pipe machines from a single integrated supplier. |

7. Suryakanthi Engineering

Shringar Engineering & Energy Systems Pvt. Ltd., trading as Suryakanthi Engineering (Bangalore), specializes in budget-conscious brick making machinery targeting small to medium-scale manufacturers.

Their unique positioning focuses on ultra-compact, lightweight machines with the DV 860 manual model weighing just 650 to 750 kg and the electrical vibration model at 600 kg (much lighter than industry norms) making them ideal for space-constrained sites and easy relocation.

Production capacity ranges from 65 to 1,000 blocks per hour across manual, semi-automatic (S4-24), and fully automatic (S3-20) models. The S4-24 features 13.45 kW power consumption, 22 KN vibration force and 850×550 mm pallet size with 24 to 30-second cycle times.

These machines operate with hydraulic systems rated at 3 to 3.5 kg pressure using 18-liter hydraulic tanks and produce solid blocks, hollow blocks, paver blocks and fly ash bricks. Suryakanthi offers three changeable mold types per machine at entry-level pricing, which makes them an excellent choice for smaller companies.

| Pros | Contras |

|---|---|

| ✅ Compact machine footprint and lightweight construction (600 to 750 kg for manual models) enable operation in small workshops and easy transportation between job sites. | ❌ Lower hydraulic pressure ratings may not meet specifications for high-strength applications. |

| ✅ Three interchangeable mold types included as standard across all models eliminates additional mold purchase costs and increases product versatility immediately. | |

| ✅ Low 3 HP hydraulic motor requirements on entry models reduce electrical infrastructure demands, making them suitable for areas with limited power availability. |

8. Aneco India

Aneco India (operating as Eco Green Tech Solutions) uniquely specializes in green technology initiatives and complete turnkey fly ash brick projects with full automation, making them eco-friendly construction machinery specialists.

Their production capacity ranges from 500 to 2,000 blocks per hour. They also offer integrated batching plants with 3-bin feeders and automatic water and cement feeding systems designed specifically for fly ash utilization.

The company's fully equipped manufacturing facility produces automatic and fully automatic hydraulic machines for fly ash bricks, concrete blocks, paver blocks, hollow blocks, interlocking bricks, and solid blocks, all engineered to promote sustainable building materials from industrial waste.

| Pros | Contras |

|---|---|

| ✅ Optimized machinery for eco-friendly brick production, reducing environmental impact while maintaining structural performance. | ❌ Established in 2007, making them relatively newer compared to manufacturers with multi-decade track records. |

| ✅ State-of-the-art manufacturing facility in Mehsana ensures consistent quality control and allows for customized automation solutions. | |

| ✅ Annual turnover of ₹5-10 crore demonstrates financial stability and established market presence. |

9. Royal Tile Machines

Royal Tile Machines is a vertically integrated paver and tile machinery specialist. They manufacture not only block making machines but also complementary products including rubber moulds, paver tiles, vibrators, color mixers, chemical hardeners and lacquer polish coatings under one roof.

The company manufactures manual, semi-automatic, and automatic models, with affordable pricing. These include interlock paver block machines, hollow block machines, concrete paver block machines, tile press machines and fly ash brick machines with production output from 2,000 to 4,000 pieces per shift for various brick sizes (60 mm, 80 mm, 100 mm thickness).

| Pros | Contras |

|---|---|

| ✅ Vertical integration allows one-stop procurement of machines plus all required accessories (moulds, hardeners, colors, polish). | ❌ Conflicting establishment dates (1998, 2000, 2003) across official sources raise questions about company transparency. |

| ✅ Oil cooling systems standard across product range prevent hydraulic overheating during continuous operation, extending component lifespan. | |

| ✅ Mechanical and electrical interlock safety systems ensure operator protection and prevent machine damage. |

10. Perfect Hydraulic Machines

Perfect Hydraulic Machines is a concrete block making machine manufacturer, but their real strength (as indicated by happy customers) lies in remote troubleshooting and phone-based technical support.

Customer testimonials consistently highlight that 90% of maintenance issues are resolved via telephone without requiring on-site visits, dramatically reducing downtime and stress. Aside from their highly regarded tech support, they also offer various block making machines to suit different needs.

Their PHM model series (PHM-04, 05, 06, 07, 08) encompasses fully automatic single and multi-cavity machines with hydraulic press and vibro compression technology complete with electrical panels. The flagship PHM-06 multipurpose plant produces paver blocks, fly ash bricks, solid blocks, hollow blocks, concrete blocks and curb stones from a single machine platform.

Perfect Hydraulic maintains in-house engineering for all machinery development, ensuring quality control and precision. Customer testimonials document 12+ years of success in the industry.

| Pros | Contras |

|---|---|

| ✅ Industry-leading remote support capability resolves 90% of technical issues via phone, minimizing production downtime. | ❌ Partnership business structure may limit financial resources for large-scale R&D compared to corporate competitors. |

| ✅ Multi-purpose PHM-06 platform versatility allows manufacturers to switch between multiple product types in one machine. | |

| ✅ Heavy gauge construction with periodic inspection, calibration and upgrade protocols. |

Top 10 Concrete Block Making Machine Manufacturers in India FAQs

What's the average cost of a concrete block making machine in India?

Prices range from ₹75,000 to ₹110 lakh, depending on automation level and capacity. Manual machines start at ₹75,000-₹2 lakh, semi-automatic models cost ₹2-₹30 lakh and fully automatic production lines range from ₹30 lakh to ₹110 lakh. Budget for additional costs including molds, batching plants and installation.

Can one machine produce multiple types of blocks?

Yes, most modern concrete block making machines produce multiple product types by changing molds. The ability to make multiple products from the same machine platform maximizes production flexibility and return on investment.

Volver arriba: Top 10 Concrete Block Making Machine Manufacturers in India

Soy Chao Zhang, llevo más de 10 años trabajando en la industria de la fabricación de ladrillos. Tengo un profundo conocimiento e investigación sobre varios modelos de máquinas de fabricación de bloques, especialmente máquinas automáticas de ladrillos, máquinas de bloques de hormigón, máquinas de bloques de tierra comprimida, máquinas de ladrillos de arcilla, máquinas de ladrillos de cemento. Tengo un conocimiento especial de esta industria. Puedo ayudar a mis clientes a elegir la máquina de ladrillos adecuada y ayudarles a diseñar y construir una fábrica de producción de ladrillos. Si desea saberlo todo sobre las máquinas para fabricar ladrillos, póngase en contacto conmigo. Estaré encantado de ayudarle.