La demanda de equipos de fabricación de ladrillos duraderos y ecológicos sigue creciendo en todo el sector de la construcción. Tanto si está creando una nueva fábrica de ladrillos como si está ampliando una ya existente, la elección de los fabricantes adecuados de máquinas para fabricar ladrillos de arcilla es importante para el éxito a largo plazo.

Esta guía enumera las principales empresas que ofrecen máquinas de fabricación de ladrillos de buena calidad, un servicio fiable y tecnología probada para la fabricación y producción eficientes de ladrillos.

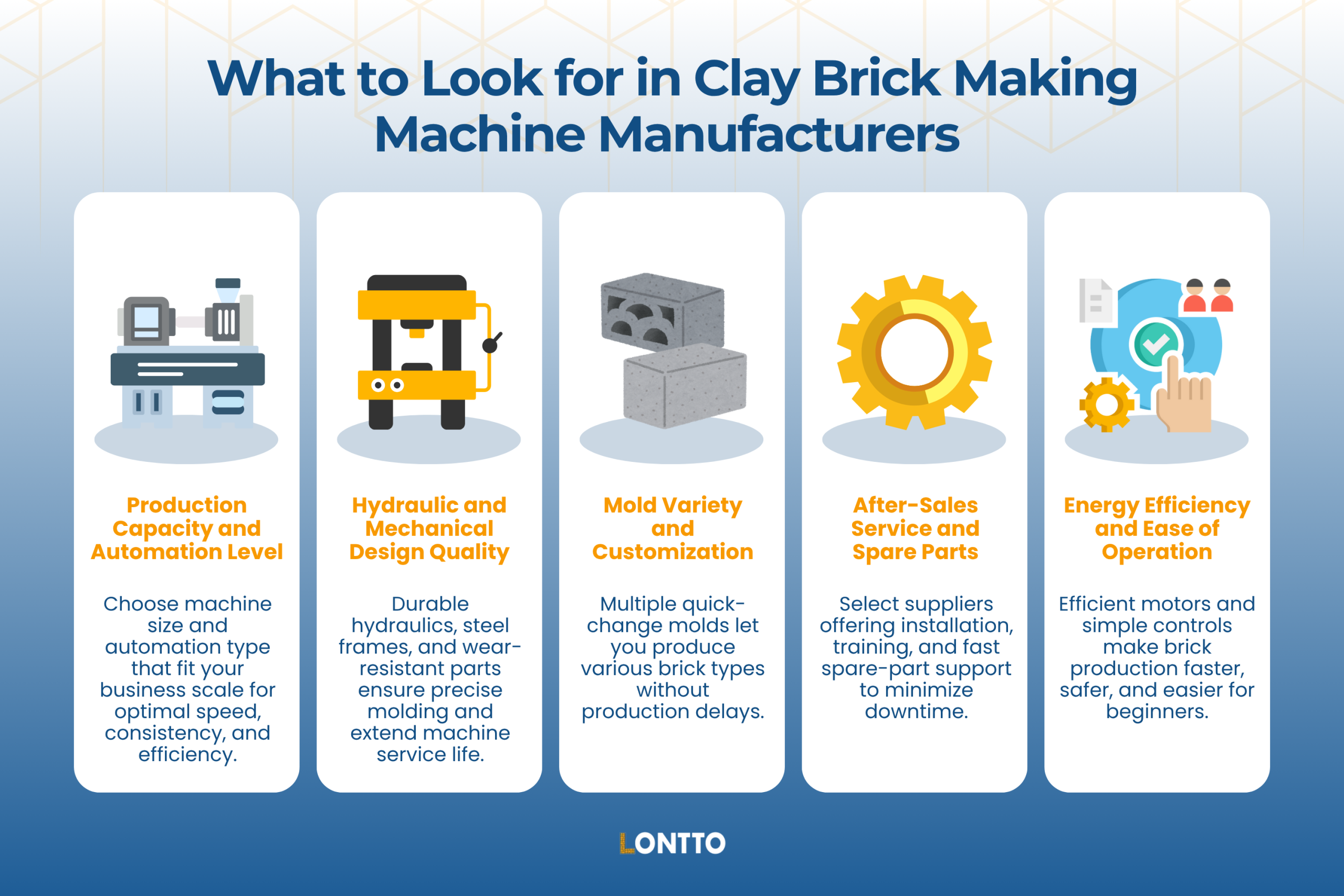

Qué buscar en los fabricantes de máquinas para fabricar ladrillos de arcilla

La elección de los fabricantes adecuados de máquinas para fabricar ladrillos de arcilla determina la eficacia con la que funciona su fábrica de ladrillos y el tiempo durante el que su máquina suministra ladrillos de buena calidad. Concéntrese en estos cinco factores antes de invertir en cualquier máquina de fabricación de ladrillos o línea de producción:

- Capacidad de producción y nivel de automatización: Adapte el tamaño de la máquina y el tipo de automatización a la escala de su negocio. Las máquinas totalmente automáticas mejoran la velocidad y la uniformidad, mientras que las máquinas manuales para ladrillos son adecuadas para operaciones pequeñas y medianas.

- Calidad de diseño hidráulico y mecánico: Los potentes sistemas hidráulicos, los sólidos bastidores de acero y los componentes resistentes al desgaste prolongan la vida útil y mejoran la precisión del moldeo de ladrillos.

- Variedad de moldes y personalización: Los principales fabricantes de máquinas de fabricación de ladrillos suministran múltiples juegos de moldes para producir diversos tipos de ladrillos, como ladrillos de arcilla, ladrillos de cemento, ladrillos de pavimentación o ladrillos huecos. Los sistemas de cambio rápido de moldes permiten a los operarios cambiar de producto sin detener la producción de ladrillos.

- Servicio posventa y piezas de repuesto: Un proveedor de máquinas fiable proporciona asistencia para la instalación, la formación y las piezas de repuesto. Los fabricantes y proveedores locales o regionales acortan los plazos de entrega de las piezas de repuesto, manteniendo el funcionamiento de la máquina sin problemas y de forma eficiente.

- Eficiencia energética y facilidad de uso: La mejor maquinaria para ladrillos utiliza motores eficientes y controles intuitivos, lo que permite incluso a los nuevos fabricantes de ladrillos empezar a fabricar ladrillos con confianza y seguridad.

Los 9 mejores fabricantes de máquinas para fabricar ladrillos de arcilla

1. Máquina de bloques Lontto

Lontto Block Machine es uno de los principales fabricantes de máquinas para fabricar ladrillos de arcilla, con más de 30 años de experiencia en el sector. La empresa diseña y produce máquinas de fabricación de ladrillos que abarcan máquinas manuales, semiautomáticas y totalmente automáticas para diferentes necesidades de producción.

Sus equipos admiten tanto la producción de ladrillos de arcilla como la de ladrillos de cemento, utilizando sistemas hidráulicos de precisión y armazones de acero duraderos para mantener una larga vida útil. Cada máquina de ladrillos viene equipada con moldes personalizables que pueden producir varios tipos de ladrillos, incluidos ladrillos entrelazados, ladrillos para pavimentación, ladrillos huecos y bloques macizos.

Sus máquinas son fáciles de manejar, por lo que resultan ideales para pequeños y medianos fabricantes que desean ampliar su capacidad de fabricación de ladrillos. La serie de máquinas automáticas para ladrillos de arcilla LT de Lontto, entre otras, está diseñada para ofrecer un alto rendimiento, una compactación uniforme y una producción de ladrillos fiable en condiciones de uso continuo.

| Pros | Contras |

|---|---|

| ✅ Utiliza componentes hidráulicos de alta calidad para producir productos de arcilla densos y duraderos y ladrillos de buena calidad en cada lote. | ❌ Los gastos de transporte y aduana no están incluidos en el precio estándar para los compradores extranjeros. |

| ✅ Máquinas manuales y sistemas de fabricación de ladrillos totalmente automáticos que se adaptan a todas las necesidades. | |

| ✅ Red de asistencia internacional probada que ofrece instalación, formación y servicio técnico para fabricantes de maquinaria globales en China y en el extranjero. |

2. Halstec Engineering Co., Ltd

Halstec Engineering Co., Ltd es uno de los fabricantes de máquinas de fabricación de ladrillos de arcilla más avanzados de China, conocido por sus sistemas de máquinas de ladrillos a gran escala y sus configuraciones completas de líneas de producción de ladrillos. La empresa está especializada en tecnologías de máquinas de ladrillos de arcilla y máquinas de fabricación de ladrillos, y ofrece plantas llave en mano que pueden producir ladrillos con una capacidad de hasta 150.000 unidades al día.

El diseño de cada fabricante de máquinas incluye extrusoras hidráulicas, secadoras y hornos de túnel diseñados para ofrecer una larga vida útil y un rendimiento constante. Halstec se centra en máquinas industriales que integran sistemas de control automático y moldes precisos para dar forma a la arcilla estructural y otros tipos de materiales de construcción.

Su gama de equipos para ladrillos de arcilla abarca máquinas manuales, máquinas totalmente automáticas y configuraciones personalizadas para fábricas de ladrillos pequeñas y medianas. Todas las máquinas son fáciles de manejar y ofrecen ladrillos de buena calidad con un consumo de energía reducido y menos requisitos de mantenimiento.

| Pros | Contras |

|---|---|

| ✅ Proporciona líneas completas de producción de ladrillos con máquinas totalmente automáticas capaces de manejar grandes producciones diarias y múltiples tipos de ladrillos. | ❌ Los plazos de entrega de las máquinas de fabricación de ladrillos diseñadas a medida pueden ser más largos debido a la configuración de fábrica y la logística de exportación. |

| ✅ La sólida tecnología de extrusión hidráulica garantiza una compactación densa de los ladrillos de arcilla y una textura uniforme para obtener resultados de buena calidad. | |

| ✅ Ofrece asistencia para la instalación, la puesta en marcha y la formación para ayudar a los fabricantes de ladrillos a empezar a fabricar ladrillos de forma eficiente. |

3. Xi'an Brictec Engineering Co.

Xi'an Brictec Engineering Co., Ltd. es uno de los principales fabricantes de máquinas de fabricación de ladrillos de arcilla de China, y ofrece soluciones completas de líneas de producción de ladrillos para operaciones de fábricas de ladrillos industriales.

La empresa se centra en sistemas de extrusión, apilado y secado de ladrillos de arcilla, integrando extrusoras de vacío avanzadas, apiladoras automáticas y tecnología de horno de vanguardia. Estas máquinas de fabricación de ladrillos están diseñadas para manipular productos de arcilla de forma eficiente, ofreciendo un rendimiento de fabricación de ladrillos de alta densidad con un menor consumo de energía.

Las máquinas de fabricación de ladrillos de Brictec están equipadas con sistemas de control inteligentes que automatizan la alimentación, el corte y el apilado, reduciendo la intervención manual y mejorando la consistencia. El diseño de cada fabricante de máquinas cumple las normas modernas de fabricación de ladrillos, ofreciendo una larga vida útil, un bajo mantenimiento y una fácil integración en las líneas de producción existentes.

Con una sólida capacidad de I+D y asistencia técnica, Brictec sigue siendo un fabricante de confianza de sistemas de ladrillos para el sector de la construcción.

| Pros | Contras |

|---|---|

| Suministra instalaciones completas de ladrillos de arcilla, incluidas extrusoras de vacío, cortadoras y secadoras para la producción continua de ladrillos. | ❌ La documentación y la logística de exportación pueden variar según la región para los compradores de fuera de China. |

| ✅ La maquinaria de fabricación automatizada con control PLC mejora la precisión, reduce los residuos y mantiene la buena calidad de los ladrillos. | |

| ✅ Amplia cartera que abarca máquinas manuales, máquinas automáticas y soluciones híbridas para pequeños y medianos fabricantes de ladrillos. |

4. Zhengzhou Yingfeng Machinery Co.

Zhengzhou Yingfeng Machinery Co., Ltd. es un nombre de confianza entre los fabricantes de máquinas de fabricación de ladrillos de arcilla en China, produciendo máquinas fiables de fabricación de ladrillos y máquinas de bloques para clientes nacionales e internacionales.

Diseñan y fabrican máquinas de fabricación de ladrillos de arcilla capaces de dar forma a materias primas como arcilla, pizarra y cenizas volantes para obtener ladrillos resistentes y duraderos adecuados para diversas aplicaciones de la construcción.

Su cartera de maquinaria para ladrillos incluye prensas hidráulicas para ladrillos, máquinas manuales y máquinas totalmente automáticas apoyadas por hornos de túnel y secadores. Los sistemas de maquinaria para ladrillos de Yingfeng se caracterizan por su robusta construcción de acero, su eficiente control hidráulico y sus interfaces de fácil manejo para simplificar el funcionamiento de la máquina. Con un rendimiento constante y una producción de ladrillos de buena calidad, la empresa es un proveedor fiable de maquinaria para fábricas de ladrillos pequeñas y medianas.

| Pros | Contras |

|---|---|

| ✅ Soluciones integradas de líneas de producción de ladrillos que incluyen mezcladoras, extrusoras y hornos para apoyar la fabricación de ladrillos a escala. | ❌ El servicio técnico local limitado fuera de Asia puede requerir asistencia remota para la solución de problemas. |

| ✅ Máquinas de fabricación de fácil mantenimiento construidas con bastidores duraderos para un rendimiento a largo plazo y una producción de buena calidad. | |

| ✅ Los sistemas hidráulicos de alta eficiencia prolongan la vida útil en condiciones de funcionamiento continuo. |

5. Tabrick

Tabrick es un fabricante mundial de máquinas de fabricación de ladrillos de arcilla que ofrece soluciones avanzadas de fabricación de ladrillos tanto para plantas de nueva creación como para fábricas de ladrillos a gran escala. La empresa fabrica máquinas de fabricación de ladrillos diseñadas para producir diversos tipos de ladrillos, incluidos los de arcilla.

Las máquinas totalmente automáticas de Tabrick integran sistemas hidráulicos de precisión y motores de alta eficiencia para ofrecer un moldeado uniforme de los ladrillos y una densidad constante en cada lote. Todas las máquinas son fáciles de manejar y están diseñadas para funcionar sin problemas con paneles de control fáciles de usar. Son fáciles de manejar para todos los niveles de experiencia.

Su proceso de fabricación de máquinas de ladrillos se centra en la calidad y la durabilidad, garantizando que cada unidad proporcione ladrillos de buena calidad y un rendimiento estable en ciclos de producción continuos.

| Pros | Contras |

|---|---|

| ✅ El diseño hidráulico energéticamente eficiente mejora la compactación y reduce los costes de funcionamiento al tiempo que prolonga la vida útil. | ❌ Las piezas de repuesto para los modelos más antiguos de maquinaria para ladrillos pueden tener una disponibilidad regional limitada. |

| ✅ Proveedor mundial de maquinaria con envío rápido y asistencia posventa para fabricantes y proveedores de todo el mundo. | |

| ✅ Fabricantes de máquinas fiables en China que proporcionan paquetes completos de líneas de producción de ladrillos con formación e instalación. |

6. Industrias de ingeniería Sadhana

Sadhana Engineering Industries es uno de los fabricantes de máquinas de fabricación de ladrillos de arcilla más conocidos de la India, especializado en máquinas de fabricación de ladrillos de tierra y equipos de producción de ladrillos ecológicos. Sus máquinas están diseñadas para materias primas de tipo arcilla y tierra, y producen hasta 1.000 unidades por turno.

Las máquinas de ladrillos manuales y los modelos semiautomáticos de la empresa son ideales para los fabricantes de ladrillos locales que necesitan producir ladrillos a partir de arcilla natural y tierra.

Centradas en la sostenibilidad, las prensas hidráulicas y mecánicas de Sadhana mantienen una compresión uniforme, ayudando a los usuarios a producir ladrillos de buena calidad a menor coste. Sus máquinas, fáciles de mantener, son un sólido punto de partida para las empresas en expansión del sector de la construcción.

| Pros | Contras |

|---|---|

| ✅ Adecuado para aplicaciones de ladrillos de arcilla y tierra, ofreciendo flexibilidad en varios tipos de ladrillos. | ❌ El funcionamiento manual puede limitar la eficacia en la producción de grandes volúmenes de ladrillos. |

| ✅ Los precios asequibles convierten a Sadhana en el proveedor de maquinaria preferido para proyectos de fábricas de ladrillos de nueva creación y de base comunitaria. | |

| ✅ Las máquinas manuales, sencillas y fáciles de manejar, permiten una rápida formación de los operarios y un mantenimiento mínimo. |

7. JC Steele Máquinas para la fabricación de ladrillos y bloques

JC Steele Brick and Block Making Machines es un conocido fabricante estadounidense de maquinaria al servicio de las industrias mundiales de productos de arcilla y fabricación de ladrillos. Con más de 130 años de experiencia en ingeniería, la empresa diseña y construye máquinas de fabricación de ladrillos y bloques de arcilla de alta resistencia para grandes fábricas industriales de ladrillos.

Sus máquinas de fabricación de ladrillos incluyen extrusoras, alimentadores y mezcladoras capaces de manejar el moldeo de ladrillos a alta presión para aplicaciones de arcilla estructural. La maquinaria de fabricación de JC Steele utiliza sistemas hidráulicos avanzados para producir ladrillos de arcilla y pizarra de buena calidad con una consistencia excepcional.

Cada máquina puede producir tanto ladrillos entrelazados como ladrillos de cemento en función de la configuración, lo que permite realizar diversos proyectos de materiales de construcción.

| Pros | Contras |

|---|---|

| ✅ Máquinas de fabricación a medida diseñadas para la fabricación de ladrillos de gran volumen, adecuadas para entornos industriales pesados. | ❌ Los precios de los equipos premium pueden estar fuera del alcance de los pequeños y medianos productores. |

| ✅ Historia fiable de fabricante de máquinas con más de un siglo de experiencia en tecnología de fabricación de ladrillos y bloques. | |

| ✅ Soporte de ingeniería experto y soluciones de líneas de producción de ladrillos llave en mano para fabricantes y proveedores mundiales. |

8. Maquinaria Raytone

Raytone Machinery es un fabricante chino de máquinas conocido por producir máquinas manuales de ladrillos compactas y eficientes y máquinas de fabricación de ladrillos de arcilla diseñadas para instalaciones de fábricas de ladrillos a pequeña escala.

La línea de equipos de la empresa incluye máquinas manuales de moldeo de bloques y ladrillos Lego capaces de fabricar ladrillos a partir de arcilla, cemento o tierra como materia prima. Cada máquina es una de las opciones más prácticas para las regiones en desarrollo, ya que combina la asequibilidad con un sólido rendimiento.

Las máquinas de fabricación de ladrillos de Raytone están construidas con armazones de acero duraderos, juegos de moldes reemplazables y características sencillas de funcionamiento de la máquina que las hacen fáciles de manejar. Estas máquinas de fabricación son ideales para pequeños y medianos productores que necesitan ladrillos de buena calidad sin una automatización pesada.

| Pros | Contras |

|---|---|

| ✅ Ofrece máquinas manuales de ladrillos y modelos de máquinas de ladrillos de arcilla asequibles para fabricantes de ladrillos principiantes y rurales. | ❌ Las limitadas opciones de automatización pueden no adaptarse a las demandas de las grandes líneas de producción de ladrillos. |

| ✅ El diseño compacto y los moldes reemplazables permiten producir varios tipos de ladrillos con un tiempo de inactividad mínimo. | |

| ✅ Máquinas de fabricación ligeras y de bajo consumo ideales para la producción de bloques pequeños o interbloques. |

9. Hydraform International Pty Ltd.

Hydraform International Pty Ltd. es uno de los fabricantes de máquinas de fabricación de ladrillos de arcilla más reconocidos de África, especializado en tecnología de máquinas de fabricación de bloques y ladrillos entrelazados. Con sede en Sudáfrica, la empresa se centra en sistemas de ladrillos hidráulicos que utilizan materias primas como arcilla, tierra y cemento para producir ladrillos de buena calidad sin cocción.

La innovación de Hydraform ha ayudado a miles de fabricantes de ladrillos a establecer fábricas de ladrillos sostenibles en regiones en desarrollo, con máquinas de fabricación de ladrillos construidas para ofrecer durabilidad, movilidad y rentabilidad.

Cada máquina puede producir varios tipos de ladrillos, como interlock, adoquín y ladrillo hueco, diseñados para reducir el uso de mortero y acelerar la construcción. Son fáciles de manejar, y tanto los modelos totalmente automáticos como los manuales ofrecen a los usuarios flexibilidad en función de la escala. Con un rendimiento probado en más de 50 países, Hydraform sigue siendo un proveedor de máquinas de confianza para la industria mundial de la construcción.

| Pros | Contras |

|---|---|

| ✅ Máquinas de fabricación robustas y móviles, ideales para proyectos de fabricación de ladrillos pequeños, medianos y comerciales. | ❌ Mayor coste de inversión en comparación con las máquinas manuales básicas de ladrillos. |

| ✅ La innovadora tecnología de ladrillos hidráulicos y entrelazados reduce los costes de construcción y el impacto medioambiental. | |

| ✅ Proporciona formación in situ y asistencia técnica para el funcionamiento y el mantenimiento de las máquinas. |

Los 9 mejores fabricantes de máquinas para fabricar ladrillos de arcilla Preguntas frecuentes

¿Cuál es el coste medio de una máquina para fabricar ladrillos de arcilla?

El precio de una máquina para fabricar ladrillos de arcilla depende del nivel de automatización, la capacidad de producción y el diseño. Las ladrilleras manuales cuestan a partir de $300, mientras que las semiautomáticas y las totalmente automáticas oscilan entre $10.000 y $80.000. Las grandes instalaciones industriales de ladrillos con prensas hidráulicas y hornos cuestan más, pero ofrecen una mayor producción y una vida útil más larga.

¿Qué materiales pueden utilizarse en las máquinas de fabricación de ladrillos de arcilla?

Las combinaciones de materias primas incluyen arcilla natural, tierra, cenizas volantes y cemento. Algunos fabricantes de maquinaria de China y otros países también ofrecen sistemas que manipulan mezclas de pizarra y arena, lo que facilita la producción de ladrillos a partir de productos de arcilla disponibles localmente.

Volver arriba: Los 9 mejores fabricantes de máquinas para fabricar ladrillos de arcilla

Soy Chao Zhang, llevo más de 10 años trabajando en la industria de la fabricación de ladrillos. Tengo un profundo conocimiento e investigación sobre varios modelos de máquinas de fabricación de bloques, especialmente máquinas automáticas de ladrillos, máquinas de bloques de hormigón, máquinas de bloques de tierra comprimida, máquinas de ladrillos de arcilla, máquinas de ladrillos de cemento. Tengo un conocimiento especial de esta industria. Puedo ayudar a mis clientes a elegir la máquina de ladrillos adecuada y ayudarles a diseñar y construir una fábrica de producción de ladrillos. Si desea saberlo todo sobre las máquinas para fabricar ladrillos, póngase en contacto conmigo. Estaré encantado de ayudarle.