Both concrete blocks and bricks influence cost, strength and appearance in any construction project. A concrete block uses cement and aggregates, while a brick uses clay that’s shaped and fired.

But are concrete blocks better than bricks in terms of strength and durability? Homeowners and builders compare these options to choose the building material that fits their needs for performance, style, and budget.

What are Concrete Blocks?

A concrete block is larger than a brick and made from a mix that creates predictable strength and performance. Concrete blocks are made in molds, cured in controlled conditions and used widely because concrete blocks offer speed and versatility. Builders consider concrete blocks vs bricks based on composition and use case.

Basic Composition of a Concrete Block

A concrete block forms from cement, sand, gravel and water, then gains strength through curing. This process makes them appealing for large builds.

- Made from cement, aggregates (sand, gravel) and water.

- Often referred to as CMUs (known as concrete masonry units).

- Manufactured in molds and cured to gain strength.

Common Types of Concrete Blocks

Concrete units vary by weight, density and purpose, and concrete blocks provide different structural benefits depending on type.

- Solid blocks vs hollow blocks: Solid units carry heavier loads and resist impact, while hollow units reduce weight and allow space for reinforcement or insulation.

- Lightweight vs heavyweight blocks: Lightweight units ease handling and speed up installation, while heavyweight units increase stability and improve sound control.

- Special units (lintel blocks, corner blocks, partition blocks): These shapes streamline construction by creating uniform openings, clean corners and straight interior divisions.

Typical Uses of Concrete Blocks

Builders select concrete blocks when they need strong walls, quick installation and clean load distribution. They’re often used in:

- Foundations, boundary walls, retaining walls.

- Load-bearing and non-load-bearing walls in commercial buildings.

- Industrial structures, basements, and garages.

What are Bricks?

A brick is a fired unit that offers color, texture, and strength for visible surfaces. Bricks provide shape consistency and detail control, and many people choose bricks or concrete blocks based on design goals. Traditional bricks create warm, classic finishes.

Definition and Basic Composition

A clay brick is formed from raw clay, shaped and then hardened in a kiln. This controlled firing creates dense units valued for appearance and long-term performance.

- Usually made from clay, shale or fly ash.

- Shaped and then fired in a kiln to harden.

- Traditionally smaller and denser than concrete blocks.

Common Types of Bricks

Different bricks address structural, decorative or cost needs. They’re flexible and versatile.

- Clay bricks (common, facing, engineering): Common bricks handle everyday wall work, facing units enhance appearance and engineering units support higher loads or harsh environments.

- Fly ash bricks and other modern variations: These units use recycled material to lower manufacturing impact and often provide smoother surfaces and consistent sizing.

- Solid, perforated and hollow bricks: Solid units increase strength, perforated bricks reduce weight and hollow bricks improve insulation and are easier to handle.

Typical Uses of Bricks

People choose brick for its textured detail, aesthetic design and curb appeal in both large and small builds. It’s often found in:

- Residential homes and infill walls.

- Decorative facades and feature walls.

- Paving, landscaping, and garden features.

Differences Between Concrete Blocks and Bricks

Comparing bricks and concrete blocks highlights differences in weight, strength, energy behavior and durability. Builders decide if concrete blocks are better than bricks by reviewing performance demands, site conditions and budget.

Size, Shape and Weight

Blocks cover more area with fewer units, while brique offers more precise placement for design features. Weight differences influence how easily crews handle each unit and how much load the structure must support.

- Concrete blocks: Their size reduces installation time, but the added weight increases handling effort and requires strong foundations for support.

- Bricks: Their lighter weight makes them easier to lift and position, though the higher unit count increases labor time and joint maintenance.

Strength and Durability

Blocks often show higher compressive strength ranges, while brick performs well in moderate climates. Both materials handle load and wear differently, and climate conditions influence how long each option maintains its performance.

- Compressive strength ranges for blocks vs bricks: Blocks usually support heavier loads because their mixes and larger dimensions allow higher strength ratings, while bricks deliver stable performance but rely more on the firing process and clay quality.

- Long-term durability in different climates: Blocks resist moisture shifts and temperature swings better in wet or cold regions, while bricks stay reliable in dry or mild areas where expansion and absorption are less demanding.

- Resistance to weathering, impact and wear: Blocks tolerate repeated impact and rough conditions due to density and mass, while bricks resist surface wear but can experience gradual moisture effects over many years.

Thermal and Acoustic Performance

Different densities control heat and sound movement in unique ways, and some blocks offer better cavity insulation. Both materials help regulate indoor comfort, but their mass and structure determine how well they manage temperature and noise.

- Insulation properties: Blocks can improve insulation when their hollow cores are filled, while bricks rely on solid mass that slows heat transfer but provides less cavity space.

- Mass and density: Heavy units absorb and release heat slowly, helping stabilize interior conditions, while lighter units respond faster to outdoor temperatures.

- Isolation acoustique : Dense brick walls reduce noise effectively in small rooms and residential settings, while blocks offer strong sound control in larger walls where added thickness or cavity fills improve performance.

Moisture and Fire Resistance

Blocks resist moisture better in humid regions, while both materials manage high temperatures safely. Performance depends on density, absorption rate and how each unit responds to prolonged exposure.

- Water absorption rates and risk of dampness: Concrete blocks absorb less water due to lower porosity, reducing the chance of damp walls. Bricks take in more moisture and may require added protection in wet climates.

- Behavior in humid or wet conditions: Blocks maintain stability with fewer issues from expansion or surface growth, while bricks can experience gradual saturation that affects appearance and long-term wear.

- Fire resistance ratings and performance in high temperatures: Both materials withstand heat well, but blocks often retain strength longer in sustained fire exposure because their cores slow heat transfer.

Construction and Installation Considerations

People compare brick vs. block systems to evaluate speed, skill demands and detail control. Concrete blocks help builders finish large surfaces quickly, while laying bricks creates more refined patterns.

Speed and Ease of Construction

Blocks save time due to size, and brick construction needs more placement accuracy. Crews consider layout, joint count and handling demands when choosing between the two materials.

- Larger block size = faster wall coverage. Bigger units reduce the number of pieces needed, helping teams build wide surfaces quickly with fewer joints to align.

- Brickwork is slower but allows more intricate designs. Smaller units take longer to place but give control over curves, patterns and detailed architectural finishes.

- Blocks need steady alignment but less fine shaping, while brickwork requires trained masons who can maintain precise joints and consistent rows.

Structural and Design Flexibility

Builders choose materials based on load needs and design freedom. Each option supports different wall types and responds differently to cutting, shaping and architectural features.

- Concrete blocks carry heavier loads and work well for structural cores, while bricks fit both structural and decorative roles depending on thickness and placement.

- Blocks handle mechanical runs and openings with less effort. Bricks need more care to avoid cracking during detailed modifications.

- Bricks allow tight curves and intricate layouts, while concrete blocks support broader geometric forms and clean modern lines.

Mortar, Joints, and Finishes

Each system uses specific mixes and finishing approaches that affect the final appearance. These choices influence strength, visual style, and long-term maintenance.

- Mortar mix differences: Concrete blocks often use stronger mixes to support structural loads, and bricks use blends designed for adhesion, flexibility and detailed joint work.

- Joint thickness: Thicker joints help distribute block weight evenly, while thinner brick joints create cleaner lines and more refined visual patterns.

- Finishing options (plastering, painting, cladding, exposed finishes): Blocks accept a range of coatings for modern surfaces, while bricks can stay exposed or receive veneers to enhance texture and color.

Concrete Blocks vs Bricks Comparison

Comparing bricks and concrete blocks across cost, maintenance, and design helps clarify which option supports the needs of your project.

| Category | Briques | Blocs de béton |

|---|---|---|

| Material Costs | Higher upfront cost with pricing that changes by region and brick type. | Often lower in price with cost influenced by density, size, and finish. |

| Regional Availability | Availability depends on local clay sources and firing capacity, which affects cost. | Widely available because aggregates and cement are common materials. |

| Labour Rates | Bricklaying takes more time and requires more skill, which raises labour costs. | Block laying is faster with fewer units per wall, which lowers total labour time. |

| Maintenance and Repairs | Moderate upkeep, depending on exposure and climate. | Minimal long-term repair needs. |

| Lifespan | Brick walls remain stable for decades and often keep their appearance over time. | Block walls last for decades and perform well under heavy structural loads. |

| L'attrait esthétique | Creates a warm, classic finish that works well with traditional architecture. | Fits modern designs with clean lines once rendered or painted. |

| Style Flexibility | Supports curved forms, patterns and detailed architectural layouts. | Works well for bold shapes and simple geometric wall designs. |

| Color and Texture Options | Offers many variations in color, texture, and finish. | Accepts paint, render, cladding, and veneers for custom surfaces. |

When Concrete Blocks Might Be Better

Blocks often offer better speed and cost value than brick, making them practical for large or structural builds. Their size, strength and predictable performance help builders manage demanding conditions where reliability and efficiency matter.

Ideal Use Cases for Concrete Blocks

Projects needing load support or rapid construction often rely on block systems. Their weight, size and structural consistency make them a strong fit for complex framing and large-scale walls.

- Large commercial or industrial buildings: These structures depend on high load capacity and fast installation, and blocks create stable walls that support significant weight.

- High walls, retaining structures, and basements: Block systems manage soil pressure and moisture well, giving them an advantage in below-grade or reinforced applications.

- Projects where speed and cost efficiency are top priorities: Larger units reduce installation time and labour needs, which lowers overall project expense.

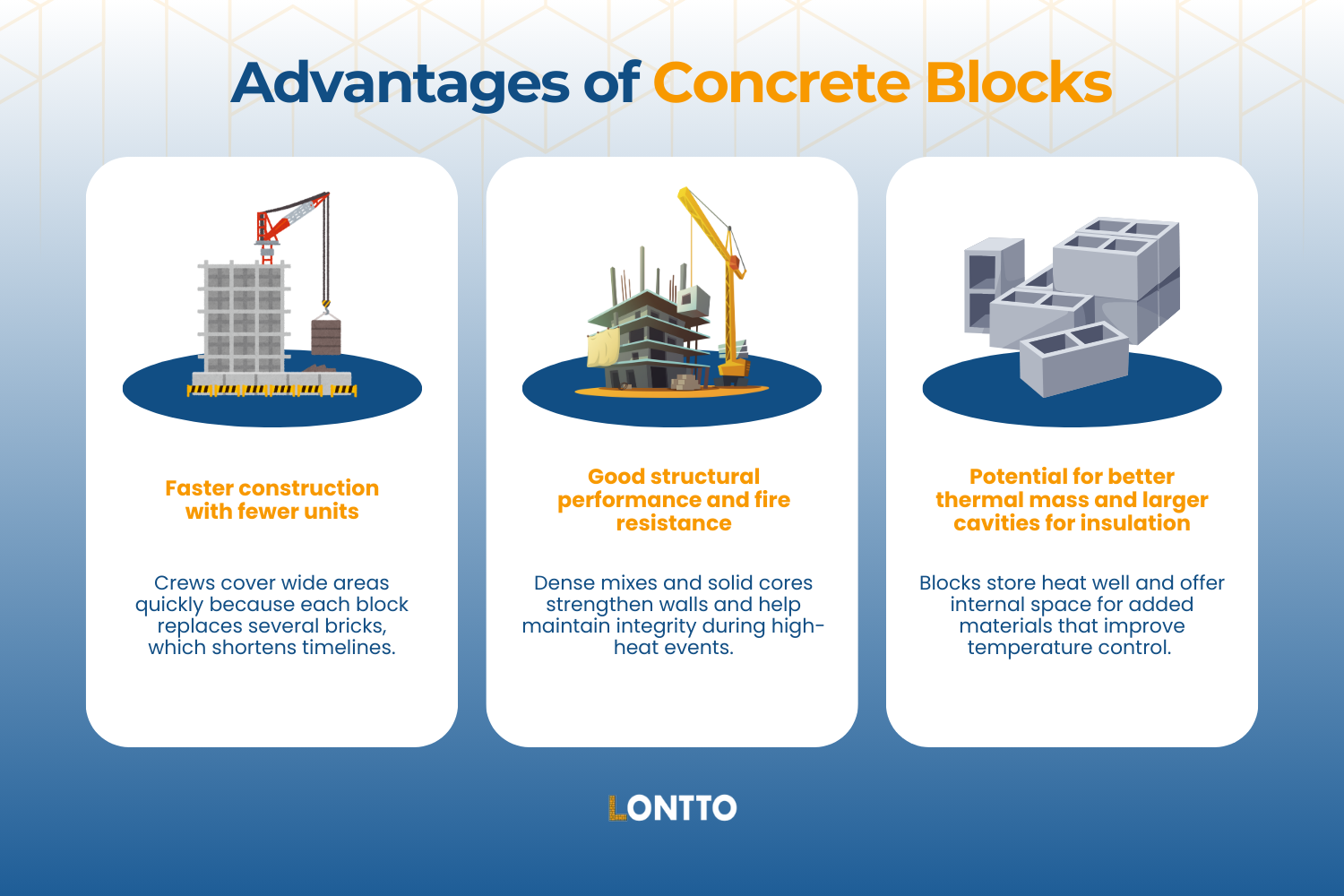

Advantages of Concrete Blocks

Blocks handle heavy loads and permit added thermal performance in cavities. Their design supports structural needs while giving builders flexibility in reinforcement and insulation placement.

- Faster construction with fewer units: Crews cover wide areas quickly because each block replaces several bricks, which shortens timelines.

- Good structural performance and fire resistance: Dense mixes and solid cores strengthen walls and help maintain integrity during high-heat events.

- Potential for better thermal mass and larger cavities for insulation: Blocks store heat well and offer internal space for added materials that improve temperature control.

When Bricks Might Be Better

Brick works well in visible areas and smaller projects where texture, color and detail matter most. Many homeowners prefer bricks for their next upgrade because the material adds warmth, character and long-term appeal to any space.

Ideal Use Cases for Bricks

Brick suits residential and historic settings. Their scale, color range and surface variation make it a strong choice for projects where appearance influences the overall feel of the design.

- Residential homes and small-scale projects: Brick creates inviting exterior and interior finishes that complement many architectural styles.

- Projects where aesthetics and character are important: Its texture and natural variation add depth and visual interest that block systems cannot easily match.

- Restoration work and heritage-style buildings: Brick aligns well with historic proportions and blends with traditional materials used in older structures.

Advantages of Bricks

Brick surfaces increase value and provide long-term stability. Their dense composition and kiln-fired strength help maintain appearance through many years of exposure.

- Timeless appearance and curb appeal: Brick offers natural color and texture that remain attractive without additional finishing.

- High durability and weather resistance: Fired clay withstands wind, sun and moisture, delivering dependable performance across climates.

- Perceived as premium in many markets: Buyers often associate brick with quality, which can elevate the overall impression of a property.

Conclusion

Are concrete blocks better than bricks? It depends on your project type, budget and design goals. Concrete blocks support fast, strong builds, while brick offers beauty and character. Some builders combine both by using a block core with brick veneer.

FAQs on Are Concrete Blocks Better than Bricks?

Can you combine concrete blocks and bricks in the same wall?

Yes, many builds use concrete blocks for structural support with a brick veneer for appearance. This approach balances load capacity with curb appeal and often appears in residential and mixed-use construction.

Are concrete blocks or bricks more environmentally friendly?

Environmental impact depends on sourcing and manufacturing. Bricks require kiln firing at high temperatures, while concrete blocks rely on cement production. Fly ash bricks and recycled-aggregate blocks reduce impact compared to traditional options.

Which is better for sound insulation between rooms?

Concrete blocks usually insulate sound better between rooms because their mass and hollow cores reduce noise transfer. Bricks still work well in residential spaces, but they rely more on wall thickness and joint quality to control sound.

Retour en haut de la page : Les blocs de béton sont-ils meilleurs que les briques ?

Je m'appelle Chao Zhang et je travaille dans l'industrie de la fabrication de briques depuis plus de 10 ans. J'ai une connaissance approfondie et des recherches sur différents modèles de machines de fabrication de blocs, en particulier les machines automatiques à fabriquer des briques, les machines à fabriquer des blocs de béton, les machines à fabriquer des blocs de terre comprimée, les machines à fabriquer des briques d'argile, les machines à fabriquer des briques de ciment. J'ai une connaissance particulière de ce secteur. Je peux aider mes clients à choisir la machine à briques appropriée et les assister dans la conception et la construction d'une usine de production de briques. Si vous voulez tout savoir sur les machines à fabriquer des briques, n'hésitez pas à me contacter. Je me ferai un plaisir de vous aider.