Connaître la différence entre les briques extrudées et les briques pressées permet de choisir le bon matériau de construction en fonction de sa résistance, de son aspect et de ses performances à long terme. Les deux types de briques sont utilisés dans le monde entier, mais la façon dont les briques sont fabriquées, leur densité, leur texture et leur manipulation sont différentes. Ces changements influencent la maçonnerie, la durabilité, la résistance au feu et l'aspect de chaque brique une fois installée.

Dans la maçonnerie moderne, les fabricants utilisent l'extrusion automatisée ou le pressage mécanique pour façonner les briques. argile, schistes et additifs en unités durables cuites dans un four. Chaque processus produit un style de brique, une finition de surface et un comportement structurel différents. Comprendre ces différences permet de sélectionner le bon type de brique pour les façades, les fondations ou les murs de soutènement dans les nouveaux projets.

Qu'est-ce qu'une brique extrudée ?

Une brique extrudée (également appelée brique en fil de fer) est fabriquée en forçant des argiles et des schistes à travers une filière en acier pour former une colonne continue. Cette méthode permet de créer des unités de taille et de forme homogènes, ce qui accélère la production de briques et uniformise l'aspect des projets de grande envergure. Après l'extrusion, une série de fils coupe la colonne en briques individuelles, en laissant des bords droits.

Les briques extrudées sont généralement percées de trous afin de réduire le poids, d'améliorer le séchage et de favoriser une liaison solide des joints de mortier. Ces trous permettent également de créer des briques plus légères et plus faciles à déplacer sur le chantier.

Les briques extrudées étant créées dans le cadre d'un processus continu, elles peuvent être produites à l'échelle. Cette uniformité en fait un choix courant pour les murs de briques commerciaux, les façades résidentielles et tous les travaux pour lesquels l'uniformité de l'apparence est importante.

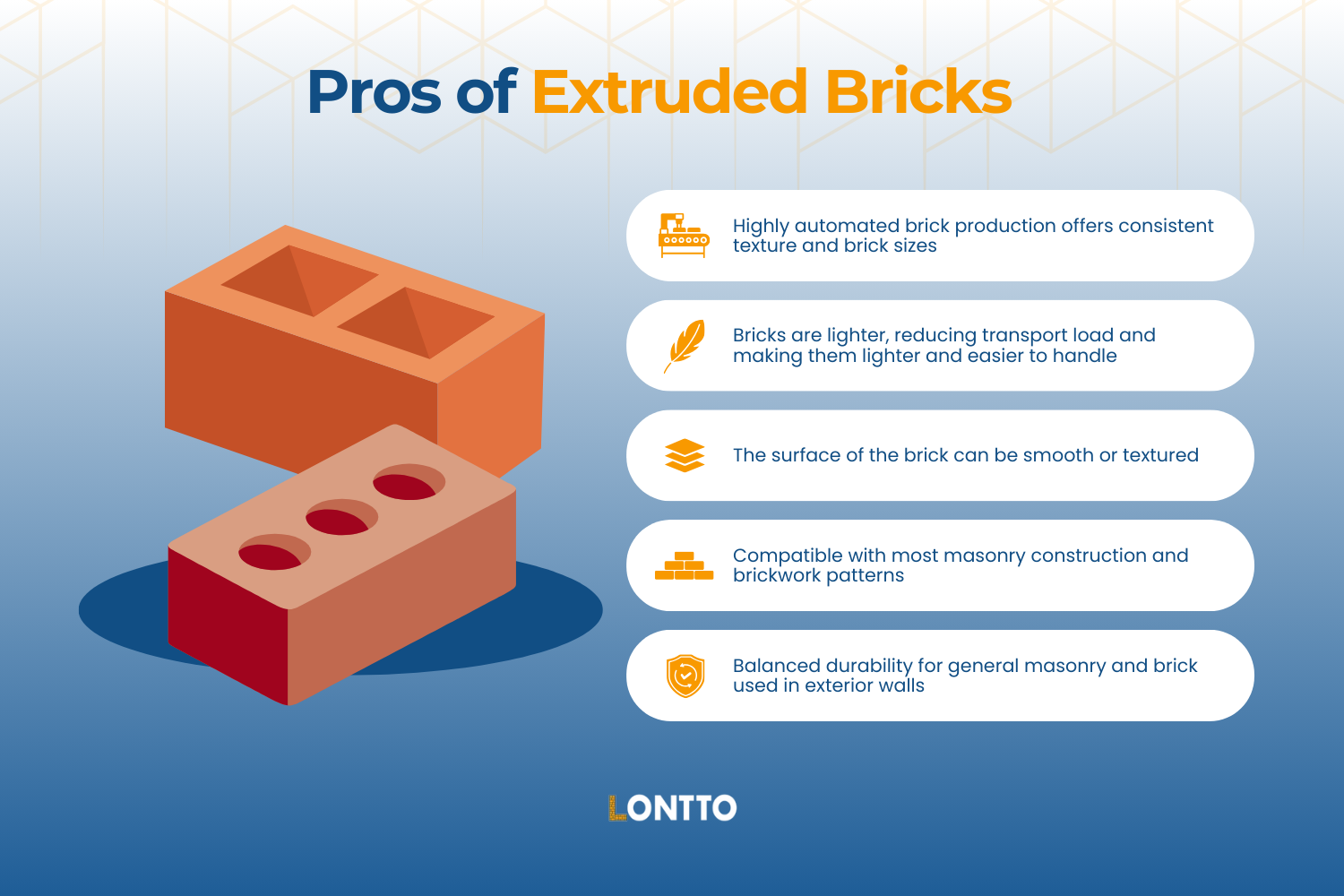

Avantages des briques extrudées

- La production de briques hautement automatisée permet d'obtenir une texture et une taille de brique constantes

- Les briques sont plus légères, ce qui réduit la charge de transport et les rend plus légères et plus faciles à manipuler.

- La surface de la brique peut être lisse ou texturée.

- Compatible avec la plupart des constructions en maçonnerie et des modèles de briques

- Durabilité équilibrée pour la maçonnerie générale et les briques utilisées dans les murs extérieurs

Les inconvénients des briques extrudées

- Selon le style de la brique, il peut y avoir des traces d'entraînement de la matrice.

- Moins dense que certaines options de briques pressées

- L'esthétique peut donner l'impression que les briques sont plus “fabriquées à la machine” que les briques traditionnelles.

- Des marques de fil apparaissent là où les briques sont coupées par le système de tranchage.

Qu'est-ce qu'une brique pressée ?

Une brique pressée (également appelée brique pressée à sec ou brique pressée à sec) est formée lorsque de l'argile raffinée est pressée dans des moules individuels sous haute pression. Cette méthode de façonnage permet d'obtenir des briques très denses aux arêtes vives, aux faces lisses et aux dimensions précises. L'argile utilisée est souvent un mélange d'argile rouge ou d'argile brûlée finement broyé, parfois fabriqué à partir d'un mélange de terres sélectionnées et d'additifs.

Une fois façonnées, les briques sont cuites dans le four, produisant une unité solide et durable avec une faible porosité. Comme ces unités se compriment sous l'effet d'une forte charge, elles atteignent souvent des niveaux de résistance à la compression élevés qui conviennent aux applications exigeantes de maçonnerie de briques et de briques à usage intensif.

Les briques pressées sont très appréciées comme briques de parement car leur face reste nette et propre après la cuisson. Les constructeurs les choisissent lorsque l'apparence est importante, comme pour les façades haut de gamme ou les travaux de restauration qui nécessitent des lignes de joints serrées et une couleur homogène.

Les avantages des briques pressées

- Les bords tranchants et les faces lisses donnent un aspect de brique de qualité supérieure.

- La densité élevée assure une excellente durabilité et une grande résistance à la compression.

- Idéal pour les briques de parement décoratives ou les travaux structurels nécessitant des tolérances serrées

- La faible absorption d'humidité améliore les performances climatiques

- Bonne performance dans les applications structurelles où l'on souhaite une brique solide.

Les inconvénients des briques pressées

- Plus lourdes que les unités fabriquées par extrusion

- Coût plus élevé en raison de cycles de pressage plus lents

- Moins léger et moins facile à poser que les options extrudées

Briques extrudées et briques pressées : Quelle est la différence ?

La différence entre les briques extrudées et les briques pressées se résume à la façon dont les briques sont fabriquées, à leurs performances et à leur aspect une fois installées. Chaque méthode modifie la densité, l'apparence, le comportement au séchage et la résistance de l'unité finale. En savoir plus sur les différents types de briques pour les projets de construction.

| Fonctionnalité | Briques extrudées | Briques pressées |

|---|---|---|

| Production | Brique fabriquée par extrusion puis coupée par des fils | L'argile est ensuite pressée dans des moules sous haute pression |

| Densité | Densité modérée ; les briques sont plus légères | Briques très denses avec une finition lisse |

| Apparence | Arêtes linéaires, possibilité de textures en fil de fer | Profils pointus, esthétique raffinée |

| La force | Convient à la plupart des constructions en maçonnerie | Durabilité et résistance à la compression plus élevées |

| Manipulation | Plus léger et plus facile à poser | Plus lourd, plus lent à mettre en place |

| Utilisations | Murs résidentiels, façades commerciales, briques utilisées pour la maçonnerie générale | Façades haut de gamme, murs d'ingénierie, travaux patrimoniaux |

Où les briques extrudées sont les plus efficaces

Les unités extrudées conviennent aux projets qui exigent rapidité, efficacité et une esthétique propre et uniforme. Leur forme homogène et leurs perforations intégrées favorisent un collage solide, un alignement stable et une réduction des déchets.

Les constructeurs les utilisent pour :

- Façades de grand format où l'uniformité de l'aspect est importante

- Logements résidentiels où les briques sont utilisées en grande quantité

- Écoles, bureaux et maçonneries commerciales à motifs répétitifs

- Projets pour lesquels des matériaux plus légers et plus faciles à manipuler accélèrent l'installation

- Murs extérieurs ou intérieurs en maçonnerie de briques

Les endroits où les briques pressées sont les plus efficaces

Les briques pressées conviennent aux applications où la résistance, la précision et les finitions haut de gamme sont importantes. Les briques pressées sont également choisies lorsque des tolérances serrées, une faible absorption d'eau et des angles nets améliorent les résultats de la construction. Leur finition raffinée permet d'obtenir des détails cohérents dans les conceptions architecturales. En savoir plus sur procédé de cuisson des briques pour les unités pressées.

Les constructeurs les choisissent pour :

- Façades haut de gamme nécessitant un aspect impeccable de la texture de la brique

- Restauration du patrimoine où les méthodes traditionnelles de finition doivent correspondre aux originaux

- Murs structurels nécessitant la compression de la durabilité et de la résistance au feu

- Entrées commerciales ou aménagements paysagers où l'aspect de la brique est central

- Maçonnerie de briques denses pour les murs d'ingénierie ou les performances à long terme

FAQ sur les briques extrudées et les briques pressées

Les briques extrudées sont-elles plus faciles à installer ?

Oui. Comme l'extrusion produit des unités plus légères et plus faciles à manipuler, de nombreux maçons les trouvent plus rapides à poser, en particulier sur de larges façades ou des sections de mur répétitives.

Les briques pressées offrent-elles une meilleure résistance ?

Les unités pressées atteignent souvent une résistance à la compression plus élevée parce que l'argile se compacte sous une forte pression avant la cuisson. Cette densité favorise les applications structurelles ou techniques.

Les deux peuvent-ils être utilisés comme briques de parement ?

Oui, les briques de parement peuvent être extrudées ou pressées. Votre choix dépend de la surface de la brique, de la finition souhaitée et du budget du projet.

Qu'est-ce qui affecte la couleur finale ?

La couleur dépend de l'argile brûlée, des additifs, du processus de cuisson, de la teneur en minéraux et de la température de production des briques. Les briques rouges, les briques silico-calcaires et les unités de silicate de calcium ont toutes une cuisson différente.

D'autres types de briques sont-ils disponibles ?

Oui. Les fabricants produisent des briques en béton, des briques techniques, des briques de stock, des mélanges de cendres volantes comme des unités de cendres volantes, et des produits spécialisés pour des travaux décoratifs ou structurels.

Retour en haut de la page : Briques extrudées ou briques pressées | Quel type de brique vous convient le mieux ?

Je m'appelle Chao Zhang et je travaille dans l'industrie de la fabrication de briques depuis plus de 10 ans. J'ai une connaissance approfondie et des recherches sur différents modèles de machines de fabrication de blocs, en particulier les machines automatiques à fabriquer des briques, les machines à fabriquer des blocs de béton, les machines à fabriquer des blocs de terre comprimée, les machines à fabriquer des briques d'argile, les machines à fabriquer des briques de ciment. J'ai une connaissance particulière de ce secteur. Je peux aider mes clients à choisir la machine à briques appropriée et les assister dans la conception et la construction d'une usine de production de briques. Si vous voulez tout savoir sur les machines à fabriquer des briques, n'hésitez pas à me contacter. Je me ferai un plaisir de vous aider.