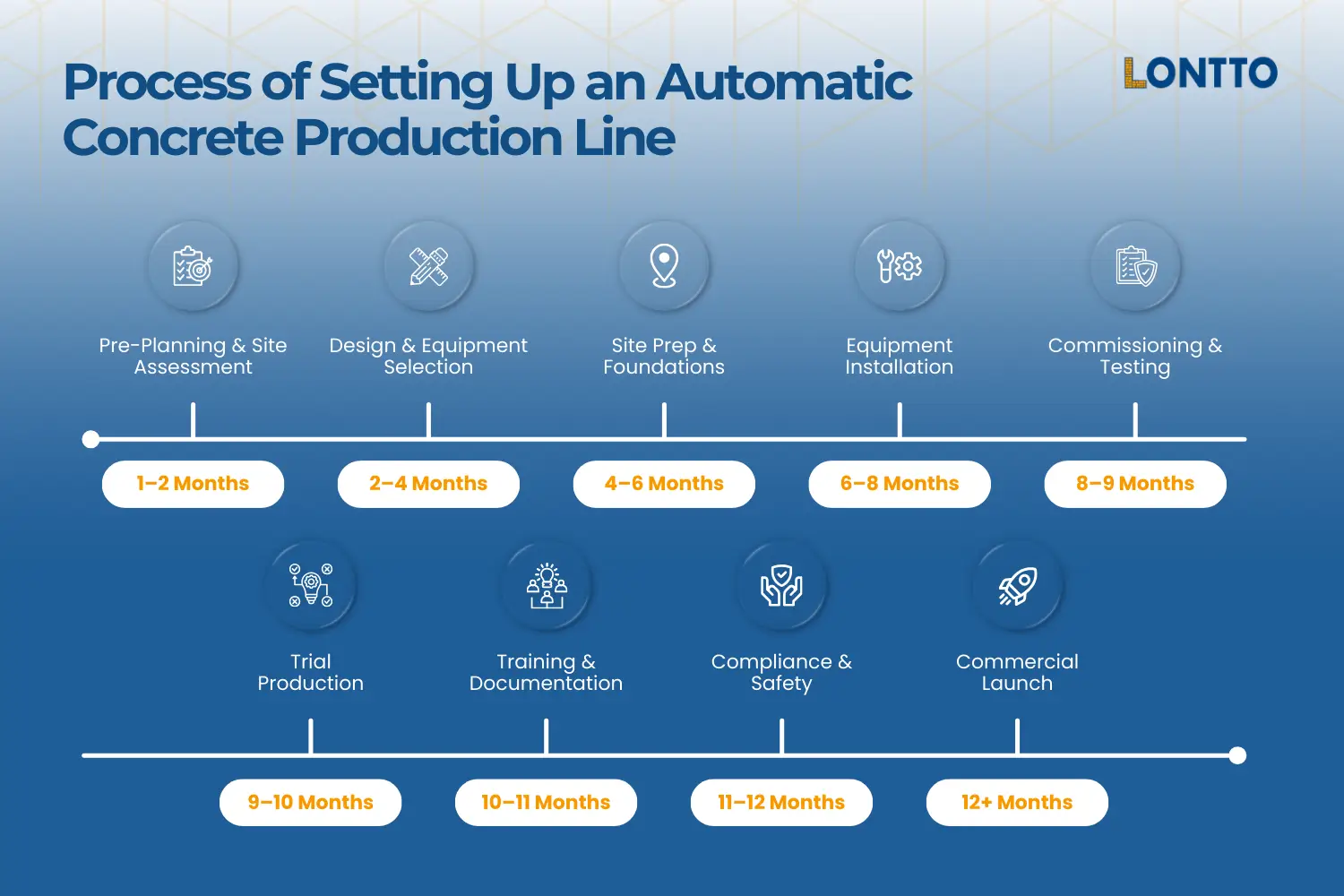

Setting up an automatic concrete production line isn’t something you can do overnight. It usually takes 12 to 24 months and involves a series of structured phases. Some steps may move quickly, others might not apply to your project at all, but each one plays an important role in making sure your operation runs smoothly and safely.

This guide walks you through how to set up a production line for concrete blocks from start to finish. You’ll see what needs to be done at each stage, which resources and equipment are required and how to keep everything on track until your first delivery of concrete products is ready to roll out.

Principaux enseignements

- Building a fully automatic block production line usually takes 12 to 24 months across nine key phases.

- Automation improves productivity, cuts down on human intervention and delivers consistent product quality.

- Smart planning, the right equipment and strict quality control measures are the backbone of success.

- Each production site has unique challenges, and skipping steps often leads to wasted time and compliance issues later.

| Phase | Months | Focus | Key Steps |

|---|---|---|---|

| 1. Pre-Planning & Site Assessment | 1–2 | Market, site, permits | (1) Market analysis & demand, (2) Site selection (2–3 acres, utilities, access), (3) Business plan & permits |

| 2. Design & Equipment Selection | 2–4 | Layout & machinery | (4) Plant layout design, (5) Equipment procurement (mixers, bins, silos, PLC), (6) Automation system design |

| 3. Site Prep & Foundations | 4–6 | Groundwork | (7) Site clearing & utilities setup, (8) Foundation pouring & curing, (9) Utility installation (power, water, air, telecom) |

| 4. Equipment Installation | 6–8 | Assembly | (10) Structural components (bins, silos, anchors), (11) Mechanical systems (conveyors, mixers, dust units), (12) Control system integration |

| 5. Commissioning & Testing | 8–9 | Inspection & calibration | (13) Pre-commissioning inspections, (14) Dry run testing, (15) Calibration & PLC setup |

| 6. Trial Production | 9–10 | Test runs & optimization | (16) First test batches, (17) Process optimization, (18) Performance validation |

| 7. Training & Documentation | 10–11 | Workforce readiness | (19) Operator training (automation, safety, maintenance), (20) SOPs & preventive maintenance plans |

| 8. Compliance & Safety | 11–12 | Environmental & safety systems | (21) Safety implementation (PPE, LOTO, monitoring), (22) Environmental controls (dust, water, noise, waste) |

| 9. Commercial Launch | 12+ | Full-scale production | (23) Final inspections & certifications, (24) Commercial production launch & KPI tracking |

Phase 1: Pre-Planning and Site Assessment (Months 1 to 2)

The first step in how to set up an automatic concrete production line is all about planning. Before spending on machinery or construction, you need a clear picture of market demand, site suitability and permitting requirements.

Step 1: Conduct Market Analysis and Production Requirements

Start by looking at the demand for concrete in your area. A plant is usually viable if it can sell at least 20 to 30 m³ per day. Larger projects may need a production capacity of 25 to 180 m³ per hour.

Also, check what your competitors are charging. Typical rates fall between $70 and $160 per m³. Identify which concrete types are most in demand, whether that’s ready-mix, pump mixes, or precast concrete products.

Step 2: Site Selection and Evaluation

For a stationary concrete batching plant, you’ll want at least 2 to 3 acres of industrial-zoned land with room to expand later. Make sure the soil can support a bearing capacity of at least 150 kN/m², and confirm easy access to roads and suppliers of raw materials like cement and aggregates. Utilities are just as important: you’ll need a reliable 380V to 480V power supply and a clean water source.

Step 3: Business Plan and Permits

Outline your capital investment, expected block manufacturing capacity, workforce needs and sales approach. Include financial projections to keep investors and lenders on board. On the compliance side, apply for zoning approvals, environmental permits and operating licenses for automatic production. Don’t forget to schedule an environmental impact assessment early, since this can take time to process.

Phase 2: Design and Equipment Selection (Months 2 to 4)

Once the site is secured, the next step in how to set up an automatic concrete production line is designing the layout and choosing the right equipment. A good design reduces material handling time, saves energy, and sets the foundation for smooth operations.

Step 4: Plant Layout Design

Your block making production line starts with a clear layout. Foundations need embedded anchor points strong enough to hold heavy production machines. Position aggregate bins where loaders can access them easily.

Route conveyors in ways that keep material travel distances short. Place cement silos close to weighing systems, and dedicate space for a truck loading area with proper queue management.

Step 5: Equipment Specification and Procurement

Select mixers that match your production targets. Twin-shaft mixers work well for 1 to 4 m³ batches, while planetary mixers are often used for specialized precast concrete elements. Aggregate bins should include 2 to 6 compartments with moisture sensors for accuracy.

Cement silos usually range from 50 to 500 tonnes and come with pneumatic systems for reliable feeding. Weighing systems need to reach ±1 kg accuracy, and a PLC-based control system will allow full automation and recipe management.

Step 6: Automation System Design

Automation is the key to a fully automatic block production line. The PLC should be programmed for automatic batching sequences, recipe storage and real-time monitoring. HMI touchscreen panels make operation simpler for staff, while remote access lets managers track production data and adjust settings when needed. Automated production reduces human intervention, improves productivity and keeps product quality consistent.

Phase 3: Site Preparation and Foundation Construction (Months 4 to 6)

If you’re building a new facility, this phase focuses on preparing the ground and setting strong foundations. Buying an existing building may let you skip some of these steps, but for new sites it's important to follow the engineering drawings closely.

Step 7: Site Clearing and Preparation

The first task is to clear and level the land to within ±25 mm. Vegetation, debris and obstacles must be removed. Temporary utilities, site access roads and staging areas should be established so crews can work efficiently. Its also the stage to put erosion control in place to protect the surrounding environment.

Step 8: Foundation Construction

Once the site is ready, excavation begins. Reinforcement steel (typically Grade 500 MPa at 150 mm spacing) is set, and anchor bolts are embedded to secure heavy production machines. The concrete foundation is then poured to a depth of 300 to 400 mm using a minimum C25 grade. A curing period of at least seven days is needed before any equipment installation.

Step 9: Utility Installation

With the foundation in place, focus turns to utilities. A three-phase 380V to 480V electrical supply with backup power must be installed. Water lines should be connected with both filtration and storage systems. Compressed air at 6 to 8 bar is added to support machinery, and telecommunications are set up so the control system can run smoothly once production starts.

Phase 4: Equipment Installation and Assembly (Months 6 to 8)

Once the foundations are cured and utilities are in place, the focus shifts to installing the main equipment. This stage brings together the structural, mechanical and control systems that will form the heart of the production line.

Step 10: Structural Component Installation

Begin by erecting the plant structure and access platforms using cranes. Position aggregate bins correctly and fit them with sensors and vibrators to keep batching consistent. Use pneumatic conveying systems to mount your cement silos, and install and calibrate all weighing equipment to a zero baseline.

Step 11: Mechanical Systems Installation

Mechanical systems are then added, including installing belt conveyors and screw feeders, ensuring alignment for steady material flow. The concrete mixer is mounted with its hydraulic systems, and dust collection units with air filtration are connected to maintain air quality and support product quality during production.

Step 12: Control System Integration

The final step is integrating the control system. PLC cabinets are placed in climate-controlled rooms for reliability, and all sensors and actuators are connected. Operator stations with HMI panels are set up, and communication networks are configured to allow real-time monitoring and adjustments during automated production.

Phase 5: System Commissioning and Testing (Months 8 to 9)

Before moving into mass production, the plant must go through a full round of inspections and testing. This stage ensures that the machinery, automation and safety systems are working together as intended.

Step 13: Pre-Commissioning Inspections

Begin with a thorough inspection of all components. Electrical connections and grounding must be checked, along with hydraulic and pneumatic pressures. Safety interlocks and emergency stops should be tested to confirm they function properly before the block machine is brought online.

Step 14: Dry Run Testing

Once inspections are complete, run the equipment without raw materials. Conveyor belts should align correctly and move at the right speeds. Weighing systems need to be verified with certified test weights, and the concrete mixer with its discharge system is run to confirm that cycles operate smoothly.

Step 15: Calibration and System Setup

Accurate batching and mixing are the basis of product quality. All weighing scales must be calibrated with certified weights, and mix recipes programmed into the PLC control system. Production parameters, alarm settings, and automatic sequencing are configured so the process is consistent, efficient, and requires minimal human intervention.

Phase 6: Trial Production and Quality Testing (Month 9 to 10)

Trial production is where the plant proves it can consistently deliver the required quality before moving into full scale operations. This stage confirms that the production process, quality control and system performance are all in line with design targets.

Step 16: First Concrete Batches

Start by producing small test batches using standard concrete mix recipes. Watch for uniform mixing and steady discharge, and run slump tests to check consistency. Compressive strength tests confirm that the hardened concrete meets structural requirements. Adjust water levels and mixing times as needed to improve product quality and stabilize the finished products.

Step 17: Production Optimization

Once test batches are complete, fine-tune the process. Adjust batching and mixing sequences to shorten cycle times and maintain smooth material flow. Calibrate moisture compensation systems to account for raw material variations. At the same time, run through quality control procedures and documentation to make sure theyre effective and ready for routine use.

Step 18: Performance Validation

The fully automatic block production line should now reach production rates within 5% of design capacity. Concrete quality must match specifications, with batching accuracy held within ±1 percent. Safety features, alarms and emergency stops should be tested one more time to confirm that the automated production environment is safe and ready for continuous use.

Phase 7: Operator Training and Documentation (Month 10 to 11)

A fully automatic block production line works best when operators are trained to handle automation confidently and follow clear procedures. This phase builds the skills and documentation needed for long term stability.

Step 19: Comprehensive Operator Training

Operators should learn plant startup and shutdown routines, how to switch between manual and automatic concrete modes and the safety protocols that keep production safe. Training also covers maintenance tasks and troubleshooting so downtime is kept to a minimum and machines stay in good condition. With proper preparation, the workforce can keep precast concrete products flowing at consistent quality.

Step 20: Documentation and Procedures

Every step of the production process needs to be documented. Standard operating procedures should cover mixing, batching, maintenance and quality testing. Preventive maintenance schedules must be prepared for mixers, conveyors, and the batching plant.

Quality control measures should be written down clearly to protect product quality. Its also important to record supplier details and keep an updated spare parts inventory so the block factory can keep running without interruption.

Phase 8: Environmental Compliance and Safety Implementation (Month 11 to 12)

A production line is only complete when safety and environmental measures are in place. These steps protect workers, limit environmental impact and keep the block making production line in line with regulations.

Step 21: Safety System Implementation

Provide PPE stations stocked with respirators and alkali-resistant gloves, and train staff in lockout and tagout procedures for all production machines. Confined space entry rules and chemical monitoring programs help reduce risks, giving operators the ability to work safely while managing concrete with automation.

Step 22: Environmental Controls

Air, water and noise must all be managed carefully. Dust collection systems need to be commissioned to meet air quality standards, while water treatment units should be in place for washout and runoff from batching and mixing.

Noise monitoring helps protect worker health, and waste management systems should recycle raw material by-products wherever possible. These steps limit the environmental impact of mass production and keep your block factory compliant.

Phase 9: Commercial Launch and Operations (Month 12+)

The last step in how to set up an automatic concrete production line is moving from testing into full-scale operations. By this stage, the plant should be certified, fully staffed and ready to supply customers with concrete products.

Step 23: Final Inspections and Approvals

Carry out all remaining regulatory inspections and secure the required permits, insurance and certifications. Final checks confirm that safety systems, environmental measures and quality control are in place to support ongoing automated production.

Step 24: Commercial Production Launch

With approvals complete, the plant can begin commercial deliveries of concrete block and precast concrete products. Use production scheduling and dispatch systems to organize deliveries and manage the distribution of concrete efficiently.

Track production volumes and key performance indicators with a target of maintaining efficiency above 85%. A strong quality assurance program and customer service system will help ensure finished products meet specifications and keep construction projects on schedule.

How to Set Up an Automatic Concrete Production Line FAQs

What needs to be checked for installation before I can open my automatic concrete production line?

Before commercial operations, the plant must confirm structural integrity, certified electrical and weighing systems, and functional safety mechanisms. Utilities like dust collection, water, and compressed air systems also need full testing and verification to ensure compliance and reliable performance.

How do you do dry testing and wet testing?

The dry run test begins by powering electrical systems, confirming indicator status, and starting the air compressor to reach 6–8 bar. Conveyor belts are run to verify direction and alignment, and the mixer operates empty for 5 minutes to check vibration and noise. Weighing scales are calibrated with certified test weights to ±1 kg accuracy, and all safety interlocks and emergency stops are tested.

The wet test loads aggregate bins with clean materials, fills silos with at least 10 tonnes of cement, and confirms water/admixture systems. A test recipe of 350 kg cement, 800 kg sand, 1,000 kg stone, and 175 L water is batched automatically, mixed for 90 seconds, checked for slump (75–100 mm), and sampled for 7- and 28-day strength testing.

Retour en haut de la page : Comment mettre en place une ligne de production automatique de béton

Je m'appelle Chao Zhang et je travaille dans l'industrie de la fabrication de briques depuis plus de 10 ans. J'ai une connaissance approfondie et des recherches sur différents modèles de machines de fabrication de blocs, en particulier les machines automatiques à fabriquer des briques, les machines à fabriquer des blocs de béton, les machines à fabriquer des blocs de terre comprimée, les machines à fabriquer des briques d'argile, les machines à fabriquer des briques de ciment. J'ai une connaissance particulière de ce secteur. Je peux aider mes clients à choisir la machine à briques appropriée et les assister dans la conception et la construction d'une usine de production de briques. Si vous voulez tout savoir sur les machines à fabriquer des briques, n'hésitez pas à me contacter. Je me ferai un plaisir de vous aider.