Traditional ceramics, made from clay-based materials, are used for making bricks. In construction, brick is a ceramic material made from clay that’s shaped and fired in a kiln, which places it firmly within traditional ceramics rather than advanced or engineering ceramics.

While traditional ceramics is a broad category that includes pottery, stoneware and porcelain, bricks fall under “earthenware”, a type of ceramic fired at lower temperatures compared to the others.

Manufacturers often use a mixture of clay, such as surface clay combined with fire clay or ball clay, to form a workable clay body with better strength and stability during making and firing. This blend improves performance in the kiln and supports consistent results in fabrication de briques.

Why Traditional Ceramics (Clay) are Used for Bricks

Traditional ceramics made from clay remain the standard choice for brick production because they balance cost, performance and practicality for large-scale construction use. Advantages include:

- Abundant raw material: Natural clay is widely available across regions, which keeps brick production affordable and supports a continuous supply for building materials.

- Suitable physical properties: Clay-based ceramics provide good compressive strength, fire resistance and thermal insulation once shaped and fired in a kiln, making brick reliable for structural use.

- Efficient for mass production: Clay is easy to mold, press and form, which allows brick making at scale with consistent size and quality.

- Cost-effective compared to advanced ceramics: Advanced ceramics are expensive, brittle and designed for specialized industrial use, which makes them impractical and over-engineered for everyday brick applications.

Ceramic Materials Used in Brick Types

Different brick types rely on specific ceramic materials and clay compositions to achieve the required strength, durability and performance for their intended construction use. Here’s a quick guide to the properties of different brick types.

| Type de brique | Common Red/Facing Bricks | Engineering/Dense Bricks | Shale Bricks |

|---|---|---|---|

| Materials/Clay Types | Surface clays (iron-rich common clays), often with silica/sand additives | Fire clays (higher alumina, lower impurities), sometimes blended with surface clays | Shales (compacted sedimentary clays, often iron-rich) |

| Key Characteristics | Porous to semi-vitreous, good compressive strength, affordable | Dense, low porosity, high strength and durability | Dense, textured surface, strong and weather-resistant |

| Firing Temperature | 1,650 °F to 2,010 °F (900 °C to 1,100 °C) | 2,010 °F to 2,190 °F (1,100 °C to 1,200 °C) | 1,830 °F to 2,190 °F (1,000 °C to 1,200 °C) |

| Color/Appearance | Red clay (from iron oxide) | Blue/gray, buff, or multi-toned | Varied (red, brown, textured) |

| Typical Uses | General construction walls, facing | Load-bearing, damp-proof courses, manholes | Paving, high-durability walls |

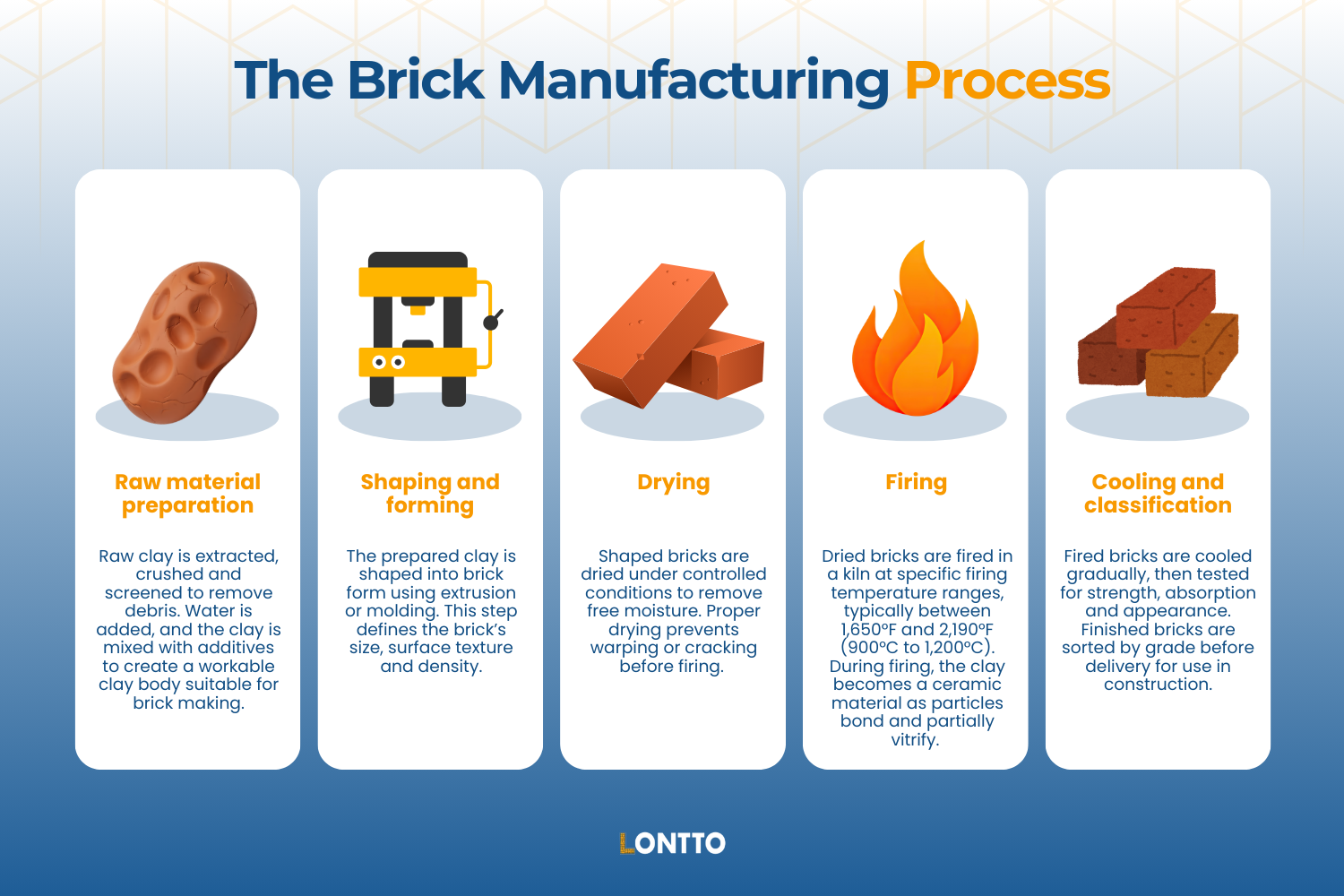

The Brick Manufacturing Process

Brick manufacturing turns raw clay into a finished ceramic brick through a controlled, multi-stage process that improves strength, durability and consistency. Each step prepares the clay material for the next stage and directly affects the final brick quality.

- Raw material preparation: Raw clay is extracted, crushed and screened to remove debris. Water is added, and the clay is mixed with additives to create a workable clay body suitable for brick making.

- Shaping and forming: The prepared clay is shaped into brick form using extrusion or molding. This step defines the brick’s size, surface texture and density.

- Séchage : Shaped bricks are dried under controlled conditions to remove free moisture. Proper drying prevents warping or cracking before firing.

- Tir : Dried bricks are fired in a kiln at specific firing temperature ranges, typically between 1,650 °F and 2,190 °F (900 °C to 1,200 °C). During firing, the clay becomes a ceramic material as particles bond and partially vitrify.

- Cooling and classification: Fired bricks are cooled gradually, then tested for strength, absorption and appearance. Finished bricks are sorted by grade before delivery for use in construction.

Additives for Strengthening Bricks

Brick making often includes additives to improve performance while keeping clay as the base ceramic material. These additions adjust shrinkage, strength, color, and firing behavior without changing the traditional ceramics used for making bricks.

- Sand or quartz: Added to the clay body to reduce shrinkage during drying and firing, which lowers the risk of cracking and helps bricks hold their shape in the kiln.

- Lime and iron compounds: Lime improves durability and firing stability, while iron oxide strengthens the brick and produces red, brown or black coloration after firing.

- Modern material variations: Some manufacturers blend fly ash into the mixture of clay, especially in large-scale production, but the brick remains made from clay or shale rather than non-ceramic materials.

These additives support strength and consistency while preserving the properties that make traditional ceramics suitable for use in brick production.

When Advanced Ceramics are Used in Bricks

Advanced ceramics are used in brick applications only in narrow industrial settings, not in standard construction. These bricks are made from high-performance ceramic materials, which allow them to withstand extreme heat, chemical exposure, and thermal shock that ordinary clay-based bricks can’t handle. Advanced ceramic materials examples include high alumina compounds or silicon carbide.

This type of brick is used in furnaces, kilns, boilers, incinerators, and chemical processing equipment that operate at high temperatures. Residential and commercial buildings don’t require this level of performance.

Which Type of Ceramics is Used for Making Bricks FAQs

What other types of ceramics are there?

Traditional ceramics include earthenware, stoneware and porcelain, all made from clay that is fired in a kiln. These materials are used for making bricks, pottery, tiles and household ware.

Advanced ceramics are engineered materials such as alumina or silicon carbide, designed for industrial use where high temperature, wear resistance or chemical stability is required rather than general construction.

What are ceramics used for?

Ceramics are used for making bricks, tiles, pottery, porcelain pieces, sanitary ware, refractories and industrial components because clay-based materials can be shaped, dried and fired to gain strength, heat resistance and long-term durability.

Is concrete a ceramic?

Concrete bricks are not ceramics. Although concrete and ceramic products may look similar in use, concrete is made from cement, aggregate and water, not fired clay. Ceramics are defined by clay that’s shaped and fired in a kiln, while concrete hardens through chemical curing at ambient temperatures.

Can bricks be made from recycled materials?

Yes, some bricks are made using recycled materials, but they still rely on clay as the primary material used. Recycled additives such as fly ash, crushed brick or industrial byproducts may be combined with other clays to improve strength or reduce waste.

Even with recycled content, these bricks remain traditional ceramics because the clay mixture is shaped and fired, which defines the ceramic brick-making process.

Retour en haut de la page : Quel type de céramique est utilisé pour fabriquer des briques ?

Je m'appelle Chao Zhang et je travaille dans l'industrie de la fabrication de briques depuis plus de 10 ans. J'ai une connaissance approfondie et des recherches sur différents modèles de machines de fabrication de blocs, en particulier les machines automatiques à fabriquer des briques, les machines à fabriquer des blocs de béton, les machines à fabriquer des blocs de terre comprimée, les machines à fabriquer des briques d'argile, les machines à fabriquer des briques de ciment. J'ai une connaissance particulière de ce secteur. Je peux aider mes clients à choisir la machine à briques appropriée et les assister dans la conception et la construction d'une usine de production de briques. Si vous voulez tout savoir sur les machines à fabriquer des briques, n'hésitez pas à me contacter. Je me ferai un plaisir de vous aider.