50000 m3 AAC Block Plant

Lontto 50000 m3 AAC Block Plant is the smallest AAC block production line. Which is special for AAC block production. AAC block is excellent building materials. It is lightweight and heat preservation and insulation.

Main tech data:

Capacity: 50000 m3/year

Materials: Fly ash, cement, quick lime, gypsum, aluminum powder.

Delivery time: 2 months.

100000 m3 AAC Block Plant

Lontto are the professional AAC block plant manufacturer in China, we have 30+ year experience of manufacturing and design. The 100000 m3 aac block plant main parts include AAC cutting machine, ball mill, slurry mixer, AAC mould, ferry cart, autoclave. This is production line for AAC block.

Main tech data:

Capacity: 100000 m3/year

Materials: Fly ash, cement, quick lime, gypsum, aluminum powder.

Delivery time: 2 months.

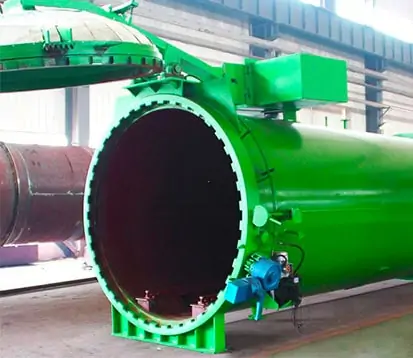

150000 m3 AAC Block Plant Autoclave

AAC block plant is specialized for autoclave aerate concrete blocks producing. The capacity can be 50000m3 – 400000m3 per year. The density of aac block can be 400-700kg/m3. All the parts and design adopt German technology.

Main tech data:

Capacity: 150000 m3/year

Materials: Fly ash or sand, cement, quick lime, gypsum, aluminum powder.

Delivery time: 2 months.

200000 m3 AAC Block Plant

200,000 m3 AAC block plant is medium sized of AAC production line. The largest capacity can be 400,000 m3 per year. This is fully automatic type plant. Any problem from the aac production line can be detected timely.

Main tech data:

Capacity: 200000 m3/year

Materials: Fly ash or sand, cement, quick lime, gypsum, aluminum powder.

Delivery time: 2 months.

300000 m3 AAC Block Plant Ball Mill

300,000 m3 AAC block plant means the capacity of AAC block 300,000 m3 per year. The advantages of AAC block are low density, good thermal insulating properties, saving time to building, good performance of preventing fire.

Main tech data:

Capacity: 300000 m3/year

Materials: Fly ash or sand, cement, quick lime, gypsum, aluminum powder.

Delivery time: 2 months.

400000 m3 AAC Block Plant

400,000 m3 AAC block plant from LONTTO construction machinery company. The production line including materials batching and mixing, the slurry pouring, cutting and autoclaving, then AAC block packing. We supply the whole production line. Please contact us for the price.

Main tech data:

Capacity: 300000 m3/year

Materials: Fly ash or sand, cement, quick lime, gypsum, aluminum powder.

Delivery time: 2 months.

Welcome to Visit Our AAC Block Plant Factory

Welcome customers from any country come to visit us, we can show you the AAC block plant workshop, and show the AAC block production site.

What is an AAC Block Plant?

An AAC Block Plant is a complete manufacturing facility designed to produce Autoclaved Aerated Concrete blocks – lightweight, energy-efficient building materials made from cement, lime, fly ash, and aluminum powder. These specialized plants use a complex 6-step process involving chemical foaming, controlled fermentation, precision cutting, and high-pressure steam curing (autoclaving) to create blocks that are 40% lighter than traditional concrete while offering superior thermal insulation.

Unlike conventional block making machines that compress concrete mix into molds, AAC plants create cellular concrete through a chemical reaction that forms millions of tiny air bubbles, resulting in blocks with exceptional insulation properties and reduced environmental impact through industrial waste utilization.

Key Features:

- Complete production lines with integrated systems from raw materials to finished products

- Annual capacity ranging from 50,000 to 400,000 cubic meters

- Advanced automation with computer-controlled batching and quality monitoring

- Steam curing technology that creates final strength and durability

- Waste-to-wealth conversion utilizing 70% fly ash from power plants

Lontto’s AAC Block Plant Components & Technology

German-engineered precision with Chinese manufacturing efficiency

Our AAC plants represent the perfect fusion of advanced European engineering standards and efficient Chinese manufacturing capabilities. Each production line features fully integrated systems with Industry 4.0 automation that ensures consistent quality while minimizing labor requirements.

Raw Material Preparation Systems

Jaw crushers and ball mills process raw materials to precise specifications, with particle size monitoring ensuring optimal fineness for superior block quality. Our automated silo systems feature load cells and level indicators that maintain continuous material flow while preventing contamination. Smart inventory management alerts operators before materials run low, preventing costly production interruptions.

The raw material handling system processes up to 50 tons per hour, with dust collection systems maintaining clean working environments while recovering valuable materials that would otherwise be lost.

Advanced Mixing & Dosing Technology

Computer-controlled batching systems deliver ingredient accuracy within ±1%, ensuring every batch meets exact specifications. Our proprietary mixing software automatically adjusts recipes based on real-time material moisture content, ambient temperature, and seasonal variations – eliminating the guesswork that leads to quality inconsistencies.

The high-intensity mixers create homogeneous slurry in just 3-4 minutes, compared to 8-10 minutes with conventional systems. This efficiency improvement increases daily production capacity by 15-20% while reducing energy consumption.

Climate-Controlled Casting & Pre-curing

Fermentation chambers maintain precise temperature (40-60°C) and humidity (85-95%) throughout the critical rising period. Advanced HVAC systems with heat recovery capture waste heat from autoclaves, reducing overall energy costs by up to 30%.

Our automated mold handling systems move 2-4 molds simultaneously, reducing cycle times and labor requirements while maintaining gentle handling that prevents cake damage.

Precision Cutting Technology

Multi-wire cutting systems slice AAC cakes with tolerances of ±1mm, producing blocks that fit together perfectly during construction. The cutting process generates less than 3% waste – significantly better than industry standards of 5-8%.

Automated cake positioning uses laser guidance for exact alignment, while vacuum lifting systems handle delicate green cakes without damage. Waste material is automatically returned to the mixing process, maximizing raw material utilization.

High-Efficiency Autoclave Systems

Our autoclave technology features rapid heating and cooling cycles that reduce energy consumption while maintaining product quality. Steam recovery systems capture and reuse thermal energy, cutting fuel costs by 25% compared to conventional systems.

Pressure monitoring and control ensures uniform curing throughout each load, while automated loading/unloading systems reduce labor requirements and improve workplace safety.

Integrated Quality Control

Real-time monitoring equipment tracks density, strength development, and thermal properties throughout production. Automated sampling and testing systems alert operators to any deviations before they affect product quality.

Digital data logging creates complete production records for quality assurance and continuous improvement analysis.

AAC Blocks Manufacturing Process

Transform industrial waste into premium building materials

AAC production represents one of the construction industry’s most successful waste-to-wealth transformations. Our process converts 70% industrial fly ash waste into lightweight, high-performance building blocks through a scientifically precise 6-step manufacturing sequence.

Step 1: Advanced Material Preparation

Fly ash processing begins with screening to remove oversized particles, followed by grinding in ball mills to achieve 4000-5000 cm²/g fineness – the optimal level for chemical reactivity. Cement and lime undergo similar preparation, with quality testing ensuring consistent chemical composition.

Aluminum powder receives special handling as the critical foaming agent, with moisture content maintained below 0.5% to ensure consistent gas generation during the expansion process.

Step 2: Precision Mixing Process

High-speed mixing occurs in specialized equipment that creates perfect homogeneity within 3-4 minutes. Temperature control during mixing prevents premature aluminum activation while ensuring optimal chemical reactions.

Water temperature and chemistry are carefully controlled, with pH adjustment ensuring optimal conditions for the aluminum foaming reaction that creates AAC’s characteristic cellular structure.

Step 3: Controlled Casting Operations

Slurry pouring into large molds (typically 6m x 1.5m x 0.6m) occurs under controlled conditions to prevent segregation. Aluminum powder activation begins immediately, creating millions of microscopic gas bubbles that expand the mixture to nearly double its original volume.

Expansion monitoring ensures consistent rise height, with environmental controls preventing temperature variations that could affect final product quality.

Step 4: Pre-curing Optimization

4-6 hours of controlled fermentation allows proper chemical reactions and strength development before cutting. Temperature maintenance at 40-50°C accelerates hydration while preventing moisture loss that could compromise block integrity.

Strength monitoring ensures cakes reach optimal cutting strength (typically 0.15-0.2 N/mm²) before advancing to the cutting station.

Step 5: Precision Cutting Operations

Wire cutting systems slice the expanded cake with mathematical precision, creating blocks with exact dimensions and smooth surfaces. Multi-directional cutting enables production of various block sizes from the same cake, maximizing material utilization.

Waste recycling returns cut materials to the mixing process, achieving near-zero material waste while maintaining consistent chemical composition.

Step 6: High-Pressure Autoclaving

12-hour steam curing at 180°C and 12 bar pressure creates final strength and durability through formation of calcium silicate hydrate crystals. Controlled heating and cooling prevents thermal shock while optimizing energy efficiency.

Final product specifications: Lightweight blocks (500-800 kg/m³) with excellent thermal insulation (R-1.25 per inch), superior fire resistance (4+ hours), and compressive strength of 3-8 N/mm² suitable for load-bearing construction up to 3 stories.

Why Choose Lontto AAC Plants

German-Standard Engineering Excellence

Our plants incorporate precision engineering standards equivalent to European manufacturers, featuring robust construction, advanced materials, and meticulous quality control throughout manufacturing. Every component undergoes rigorous testing and inspection, ensuring reliable operation in demanding industrial environments.

Cost advantages of 40-60% over European alternatives don’t compromise quality – they reflect efficient Chinese manufacturing, optimized supply chains, and volume production benefits that we pass directly to customers.

Global Success & Proven Reliability

Over 1,000 successful installations span six continents, from small regional operations to large industrial facilities producing 400,000+ m³ annually. Our plants operate reliably in extreme climates from Arctic conditions to tropical environments, demonstrating robust engineering and adaptable design.

Customer retention rates above 95% reflect satisfaction with both equipment performance and ongoing support services, with many customers expanding their operations through additional Lontto plants.

Complete Technology Transfer

Beyond equipment supply, we provide comprehensive knowledge transfer including optimized raw material formulations, quality control procedures, maintenance protocols, and market development strategies. Our technical teams work alongside your staff during startup and beyond, ensuring successful operations from day one.

Proprietary formulations developed over three decades provide competitive advantages in product quality, raw material efficiency, and production optimization that aren’t available elsewhere.

Innovation Leadership & R&D Investment

30+ patents in AAC technology reflect continuous innovation in equipment design, process optimization, and quality improvement. Our dedicated R&D center employs 100+ engineers focused on advancing AAC manufacturing technology and developing next-generation solutions.

State-of-the-art manufacturing facilities utilize the latest CNC machining, precision welding, and quality testing equipment to ensure every component meets exacting specifications.

Local Manufacturing Advantages

Three factories spanning 3.6 million square feet house 1,200+ skilled employees, including 100+ senior engineers with decades of AAC experience. This manufacturing scale enables competitive pricing while maintaining strict quality control through vertical integration.

Strategic component sourcing from qualified suppliers worldwide ensures optimal quality and cost balance, while local production provides faster delivery and responsive customer service.

Installation & Support Services

Comprehensive Project Management

Complete project scope encompasses everything from initial site evaluation through production optimization, ensuring smooth implementation without costly delays or oversights. Our project managers coordinate all aspects including equipment manufacturing, shipping, installation, and commissioning.

Site preparation guidance helps optimize plant layout for efficiency and future expansion, while our construction management services ensure facilities meet all operational requirements.

Accelerated Implementation Timeline

6-12 month delivery and installation gets you to market quickly through parallel processing of equipment manufacturing and site preparation. Modular design enables pre-testing of major systems before shipment, reducing on-site commissioning time.

Fast-track installation teams with extensive international experience minimize startup delays while ensuring proper equipment setup and calibration.

World-Class Training Programs

2-4 weeks intensive training covers all operational aspects from raw material handling through finished product packaging. Hands-on experience at our facilities or your plant ensures teams understand both routine operations and troubleshooting procedures.

Ongoing education programs keep your staff current with best practices, new techniques, and equipment updates as your operation matures and expands.

Partnership-Based Support

24/7 technical support provides immediate assistance for any operational questions or equipment issues. Remote monitoring capabilities enable our technicians to diagnose problems and provide solutions without costly site visits.

Guaranteed spare parts availability ensures maximum uptime, while periodic optimization visits identify opportunities for efficiency improvements and capacity increases.

Flexible Investment Solutions

Equipment financing options reduce upfront capital requirements while preserving cash flow for working capital and market development. Progressive payment terms align costs with project milestones, reducing financial risk during construction and startup phases.

Performance guarantees provide confidence in achieving specified production rates and quality standards, with penalty provisions protecting your investment.

Market Opportunities & Trends

Explosive Market Growth

The global AAC market grows at 7.5% annually, reaching $30.31 billion by 2034, driven by unstoppable urbanization trends, increasingly strict energy efficiency requirements, and growing focus on sustainable construction materials.

Market momentum continues accelerating as building codes worldwide adopt higher insulation standards and environmental regulations favor waste-utilization technologies like AAC production.

High-Growth Regional Markets

Asia-Pacific, Middle East, and Africa demonstrate strongest demand growth, with government policies actively promoting lightweight, energy-efficient building materials. Infrastructure investment programs in these regions create sustained demand for construction materials.

Early market entry provides first-mover advantages and market share capture opportunities before competition intensifies in these developing markets.

Clear Competitive Advantages

AAC blocks deliver superior performance with 40% weight reduction, 60% better thermal insulation, and 50% faster construction compared to traditional clay bricks. These advantages create compelling value propositions for contractors, developers, and building owners.

Energy efficiency benefits become increasingly valuable as utility costs rise and green building certifications become market requirements rather than optional features.

Sustainability & Regulatory Alignment

Converting industrial waste (fly ash) into valuable building materials aligns perfectly with circular economy principles, often qualifying projects for government incentives, tax benefits, and green building certifications.

Carbon footprint reduction through waste utilization and energy-efficient buildings appeals to environmentally conscious consumers and meets corporate sustainability goals.

Optimal Market Timing

Early entry into developing markets provides significant advantages in market share capture, customer relationship development, and distribution network establishment before international competition arrives.

Growing awareness of AAC benefits creates expanding markets even in established regions, as architects, contractors, and developers seek better alternatives to traditional materials.

Frequently Asked Questions

What’s the minimum investment required for an AAC plant?

Small-scale plants (50,000 m³/year capacity) start around $800,000, including basic equipment and installation. This entry-level investment provides access to profitable AAC manufacturing with room for future expansion. We offer flexible financing options including equipment loans and progressive payment terms to reduce upfront capital requirements and preserve working capital for market development.

How quickly can I recover my investment and achieve profitability?

Most customers achieve full investment recovery within 2.5-3 years, with some regional markets offering faster returns due to limited competition and strong demand. Monthly profitability typically begins within 6-12 months of production startup, depending on local market conditions and sales development. Cash flow positive operations usually occur within the first year as production efficiency improves and market penetration increases.

What raw materials do I need, and are they readily available locally?

Primary materials include fly ash (70% of mix), cement, lime, gypsum, and aluminum powder. Fly ash availability from power plants makes this the most economical raw material, significantly reducing production costs. Cement and lime are typically available locally, while aluminum powder and gypsum may require regional sourcing. Our team provides detailed raw material sourcing analysis for your specific location during feasibility studies.

Do you provide comprehensive training and ongoing operational support?

Yes, we include complete training covering all operational aspects from raw material handling through quality control and maintenance procedures. Technical teams receive 2-4 weeks hands-on training at our facilities or your plant. Ongoing support includes 24/7 technical assistance, guaranteed spare parts availability, remote monitoring capabilities, and periodic optimization visits to maximize efficiency and profitability.

How does Lontto technology compare to expensive European manufacturers?

We offer equivalent technology quality and performance at 40-60% lower investment costs, with faster delivery times and more flexible customization options. Our plants incorporate the same precision engineering standards while leveraging efficient Chinese manufacturing and optimized supply chains. Customer satisfaction ratings consistently exceed 95% across all regions, demonstrating that cost savings don’t compromise quality or performance.

What production capacity should I choose for my market?

Capacity selection depends on local market size, competition levels, and growth projections. Our feasibility studies analyze your specific market conditions and recommend optimal plant sizing. Starting smaller allows market development while preserving capital, with expansion capabilities built into initial designs. Most successful operations begin with 50,000-100,000 m³/year capacity and expand as markets develop.

Contact & Next Steps

Ready to start your profitable AAC manufacturing business?

Free Consultation & Analysis Services

Our experienced engineers provide complimentary feasibility studies, including detailed ROI analysis, market assessment, and plant sizing recommendations based on your specific local conditions. These comprehensive studies include raw material availability analysis, competition assessment, and financial projections tailored to your investment requirements.

No-obligation consultations help you understand the complete opportunity and make informed investment decisions with confidence.

Plant Visit & Demonstration Options

Tour our state-of-the-art manufacturing facilities in China to witness production quality and engineering excellence firsthand. We arrange complete facility tours including equipment demonstrations and meetings with technical teams.

We cater operating plant visits to provide opportunities to see AAC plants in operation, meet current customers, and understand real-world performance and profitability.

Back to top: AA Block Plants