The construction industry runs on high quality machinery. A reliable partner in hollow block machine manufacturers doesn’t just sell equipment, they help you keep projects moving on schedule and your brick production factory running smoothly.

For this list, we looked at the qualities that matter most when evaluating hollow block machine manufacturers. Each company has been evaluated on how long they’ve been in business, their global reach, the technology and certifications they bring to the table, and their overall production capacity. Every name on this list is a trusted partner with a proven track record in block machine manufacturing.

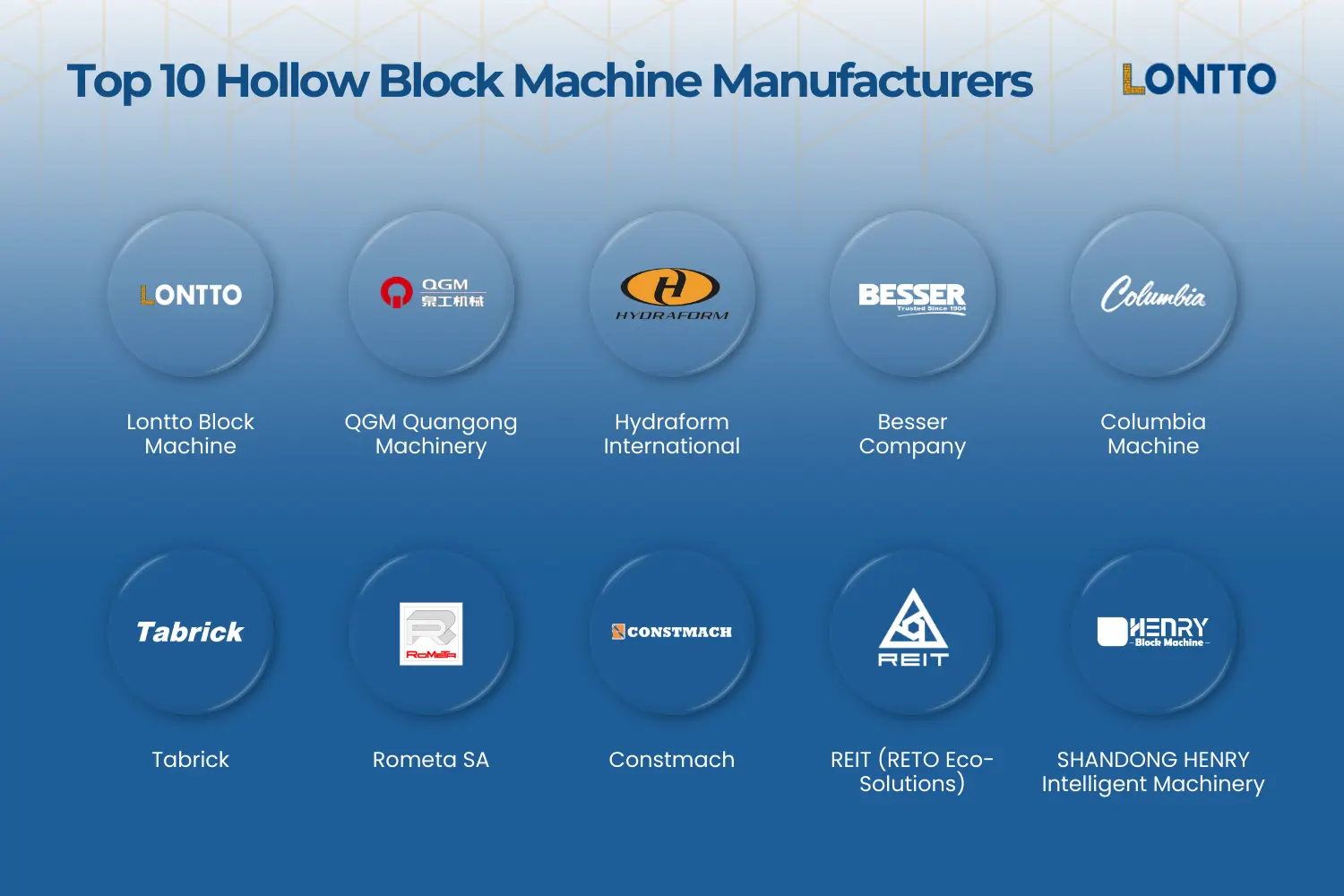

Top 10 Hollow Block Machine Manufacturers

1. Lontto Block Machine, China

Lontto is one of the most respected names among hollow block machine manufacturers, known worldwide for reliable block making machines that support both small startups and large brick production factories.

With decades of experience in the block machine manufacturing market, Lontto combines advanced design, strong after-sales service and proven durability to meet the needs of modern construction projects. Customers turn to Lontto because they don’t just deliver a machine, they deliver a complete solution for long-term success.

| Pros | Cons |

|---|---|

| ✅ Wide range of models, from manual brick-making machines to fully automatic lines | ❌ Delivery times may be longer in peak seasons |

| ✅ Strong after-sales training, installation, and parts support | ❌ |

| ✅ CE and ISO-certified machinery for global compliance | ❌ |

Company Specifications

| Been In Business For: | Over 30 years in block machine manufacturing |

|---|---|

| Global Reach: | 100+ countries with a large distributor network |

| Technology & Certifications: | CE, ISO 9001, advanced PLC control systems |

| Production Capacity: | From small manual machines up to fully automatic brick-making machines producing thousands of concrete blocks per day |

2. QGM Quangong Machinery (China/Germany)

QGM Quangong Machinery merges large-scale Chinese production with precision German engineering. Established in 1979, the company has built a global reputation for dependable block making machines that are trusted across the construction industry. With over 200 patents and decades of innovation, QGM consistently delivers both efficiency and long-term durability.

A major reason contractors and entrepreneurs choose QGM is its emphasis on technology and support. From Siemens PLC control systems to intelligent cloud monitoring and remote diagnostics, their machines are designed to make block production smoother and easier to manage. Add in strong after-sales service, CE and ISO certifications, and worldwide service centers, and it’s clear why QGM is considered a trusted hollow block machine manufacturer and supplier on nearly every continent.

| Pros | Cons |

|---|---|

| ✅ Deep engineering roots, over 200 patents and multiple national manufacturing honors | ❌ Complex systems with cutting-edge tech might require specialized after‑sales support to maintain performance |

| ✅ Range covers everything from semi‑automatic to fully automatic concrete block-making machines | ❌ |

| ✅ Advanced tech features like intelligent cloud monitoring, Siemens PLC control, plus remote diagnostics and maintenance | ❌ |

Company Specifications

| Been In Business For: | Over 4 decades (opened in 1979) |

|---|---|

| Global Reach: | Operates in more than 120 countries and regions via 35+ service branches, plus 15 overseas offices |

| Technology & Certifications: | Holds ISO 9001, ISO 14001, ISO 45001 quality systems and CE compliance. The company also integrates German frequency-conversion tech and has earned numerous high-tech enterprise awards in China |

| Production Capacity: | Offers everything from semi‑automatic block‑making setups to top-tier fully automatic production lines, including models like the mobile Zenith series and the QT series capable of forming thousands of concrete hollow blocks per shift |

3. Hydraform International (South Africa)

Hydraform has built its reputation by doing something different from most hollow block machine manufacturers. Since 1988, the company has focused on turning soil, cement, and water into strong interlocking blocks using hydraulic pressure.

Their block making machines are built to work on site, even in remote locations, which makes them a smart choice for communities and contractors that want to cut costs on materials and transport.

Beyond selling brick making machinery, they run a dedicated Training Academy in Johannesburg where builders learn how to operate the machines, prepare soil mixes, maintain equipment and even market their block businesses. This approach has helped Hydraform spread across 50 countries and become a trusted name in sustainable building solutions.

| Pros | Cons |

|---|---|

| ✅ Produces interlocking blocks with locally available soil and less mortar | ❌ Interlocking methods may be unusual for builders |

| ✅ Mobile and modular machines ideal for rural or remote building sites | ❌ |

| ✅ Strong customer support, training and skills development | ❌ |

Company Specifications

| Been In Business For: | Over 35 years, founded in 1988 |

|---|---|

| Global Reach: | Active in 50+ countries with strong presence in Africa and beyond |

| Technology & Certifications: | ISO accredited, recognized by Agrément South Africa for tested building performance |

| Production Capacity: | Machines range from mobile models producing about 1,700 blocks a day to larger units capable of 6,000 blocks daily |

4. Besser Company (USA)

Besser might feel like a name from the early days of block machine manufacturing, because it is. The company was born back in 1904 when Jesse Besser invented one of the very first hand‑tamp block machines in Alpena, Michigan, creating what became known as the “Besser block” and setting a global standard for block production.

Today, Besser is still going strong as a leader in concrete production systems, molds, robotics and training, serving the machine market with innovation and a people-centered approach.

They offer everything from production machines and molds to industry-grade training and 24/7 parts support. Whether you’re running a large-scale brick production operation or need concrete block-making solutions with strong support, Besser offers both the equipment and the expertise to back it up.

| Pros | Cons |

|---|---|

| ✅ A century-old legacy with deep roots in concrete block innovation | ❌ Potentially longer lead times or higher costs for clients seeking small-scale or simpler block machines |

| ✅ Complete ecosystem from production machines and molds to comprehensive training and support | ❌ |

| ✅ Employee-owned model means passionate, invested teams focused on quality and service | ❌ |

Company Specifications

| Been In Business For: | Over 120 years |

|---|---|

| Global Reach: | Machines and systems deployed in over 130 countries |

| Technology & Certifications: | Known for continuously advancing machinery, from initial hand tamp to modern robotics and automation; strong safety and training foundation |

| Production Capacity: | Offers heavy-duty production systems capable of high-output concrete block-making, plus specialized molds |

5. Columbia Machine (USA)

Columbia Machine has been turning the concept of block making on its head since the 1940s. Founded in Vancouver, Washington, this company started out repairing primitive block machines and quickly innovated to build one of the first semi‑automatic, hydraulically operated block machines in 1945. The brand is now recognized in over 100 countries.

What really brings Columbia into a league of its own is how they back up their machines. Their global sales and service network makes sure you’re not left hanging with emergency parts and after hours support. These are the kinds of hollow block machine manufacturers that feel personal and dependable.

| Pros | Cons |

|---|---|

| ✅ A rich legacy in block machine manufacturing with over 85 years of innovation and leadership | ❌ The complexity and scale of their systems might translate to higher upfront costs and longer lead times |

| ✅ Full system provider: block machinery, batching, molds, automation, and palletizing | ❌ |

| ✅ Strong support network with training, emergency parts, and global reach to back your investment | ❌ |

Company Specifications

| Been In Business For: | More than 85 years |

|---|---|

| Global Reach: | Serves customers across more than 100 countries, with operations spanning North America, Latin America, Africa, Europe, the Middle East, India, China, and the Pacific Rim |

| Technology & Certifications: | Known for durable, reliable machinery with hydraulic systems and modern automation; supported by a world-class customer care infrastructure including parts, training, and plant design |

| Production Capacity: | Delivers full concrete products production lines ideal for high-output operations |

6. Tabrick (China)

Tabrick started small in 1998, when two founders began designing brick-making machinery for local customers. Since then, they've grown into a high-tech enterprise that covers everything from market research and development to manufacturing, sales, and after-sales service. They’ve carved out a reputation for building brick making machines that offer durability and reliability, along with competitive pricing that appeals to both small start-ups and growing operations.

Today, Tabrick brings to the table a broad selection of block making machines, including everything from manual cement and clay brick machines to automatic and portable concrete block machines. Their QT4-15 and QT6-15 models are especially well-regarded in the concrete block machine world as they offer quality that stacks up against bigger brands but without the hefty price tag.

| Pros | Cons |

|---|---|

| ✅ Over 20 years of focus on brick making machinery development | ❌ Smaller scale than industrial giants, so their output and production lines may not suit large-scale brick production factories |

| ✅ Wide machine range from manual clay and cement machines to automatic and portable concrete block-making machines | ❌ |

| ✅ Models like QT4-15 and QT6-15 praised for high quality and affordability in industry reviews | ❌ |

Company Specifications

| Been In Business For: | Over 25 years of experience |

|---|---|

| Global Reach: | Tabrick exports its main products abroad, supplying customers in many countries across regions |

| Technology & Certifications: | Positioned as a high-tech company with strong technical development and quality control. Specific certifications (like CE or ISO) are not highlighted clearly on their site |

| Production Capacity: | Offers a spectrum of machines including small portable units up to automatic concrete block-making machines, with models like QT4-15 and QT6-15 suited for cost-effective brick production |

7. Rometa SA (Spain/Romania)

Rometa SA brings over six decades of know-how to the world of block making machines. Since starting out in 1956, this Spain-based company has quietly become a go-to name for tailored, high-quality systems that serve concrete block, ceiling block, kerbstone, and paver production. What’s refreshing about Rometa is how flexible they are. They offer anything from partial upgrades to fully customized block production plants that align closely with your needs and your space.

Their product range, with machines like the Rometa 1010, 2010, 2030, 2050, and 4050, offers clients clear choices based on output needs, from basic setups to high-output commercial lines.

| Pros | Cons |

|---|---|

| ✅ Over 60 years of experience in machine manufacturing and block-making innovation | ❌ May be less competitive for businesses looking only for compact or low-cost hollow block machines |

| ✅ Tailor-made plants and machines, customized layouts, batching, and block production to suit individual project goals | ❌ |

| ✅ Clear range of models with detailed capacity options and technology like remote control and ROI studies | ❌ |

Company Specifications

| Been In Business For: | More than 60 years |

|---|---|

| Global Reach: | Active across four continents, serving customers globally with strategic installations and support |

| Technology & Certifications: | Equipped with ISO 9001:2015 quality management certification and safety compliance with European machinery directives; uses trusted electrical and hydraulic components |

| Production Capacity: | Offers a model range with outputs from around 500 blocks/hour (Rometa 1010) up to 3,000 blocks/hour (Rometa 4050), covering standard, hollow, and specialty concrete product forms |

8. Constmach (Turkey)

Based in Izmir, Turkey, they’re best known for their concrete batching plants, crushing systems, and concrete block making machines that serve both stationary and mobile needs with equal strength. Their machines are built for durability and ease of use, making them especially popular across construction operations where performance and reliability matter most.

From fully automated systems to user-friendly models, Constmach has designed block machines and production lines that adapt across different scales of projects. Their approach blends solid engineering with smart customer support, so whether you're running a large block production line or setting up a smaller concrete block-making operation, they aim to cover the bases on performance, accessibility, and assistance’.

| Pros | Cons |

|---|---|

| ✅ Wide product range from stationary to mobile block making machine systems for flexibility in project planning | ❌ Broad product offering could mean more complexity when selecting the exact machine you need, rather than a custom-fit solution |

| ✅ Known for efficiency, durability, and low operating costs in concrete block production, thanks to robust, user-friendly design | ❌ |

| ✅ Strong after‑sales support backed by ISO‑certified manufacturing and a global export footprint across 85 countries | ❌ |

Company Specifications

| Been In Business For: | Over a decade of dedicated experience |

|---|---|

| Global Reach: | Active in 85 countries across six continents, serving clients from the US and Europe to Africa and the Middle East |

| Technology & Certifications: | ISO‑certified production with high-quality SIEMENS and SCHNEIDER PLC systems in control units; focus on efficient, sturdy machinery and thoughtful integration |

| Production Capacity: | Offers both mobile and stationary concrete block and batching systems. Capacities span small to medium-sized operations, with concrete batching capabilities ranging from 15 to 300 m³/h |

9. REIT (RETO Eco-Solutions) (China)

If you’re looking for a manufacturer that couples environmental responsibility with high‑volume production, REIT (a subsidiary of RETO Eco‑Solutions) is an excellent choice in the hollow block machine space.

Founded in Beijing in 1999, REIT has grown into China’s first block machine maker to be listed on NASDAQ, building a reputation on delivering fully automatic block machines and concrete block production lines that serve markets all around the world.

What’s impressive about REIT is how they’ve developed a split-type maintenance design for easy access during servicing, which minimizes downtime and keeps production flowing. Their R&D center, with ties to German technology and a strong focus on using sustainable materials like fly ash, shows how REIT’s machines aren’t just efficient, they’re increasingly eco-friendly. You get smart, sustainable block making machines that can scale with your business.

| Pros | Cons |

|---|---|

| ✅ China’s first NASDAQ-listed machine manufacturer, with a strong legacy in innovation and sustainability | ❌ With high-tech and eco-focused features, their machines can come with a steeper investment compared to simpler block machines |

| ✅ Offers a wide range of fully automatic brick making machinery | ❌ |

| ✅ Features like the split-type design make routine maintenance fast and hassle-free, less downtime, more production | ❌ |

Company Specifications

| Been In Business For: | Over 25 years of experience |

|---|---|

| Global Reach: | Exports its advanced systems to markets including the United States, Canada, South Korea, Russia, and more than 100 countries globally |

| Technology & Certifications: | R&D center uses German tech standards; invests in intelligent automation, eco-friendly materials like fly ash, and industrial-grade components with environmental solutions at the core |

| Production Capacity: | Offers highly automated concrete block making machines and complete production lines capable of handling high-output demands with precision and speed |

10. SHANDONG HENRY Intelligent Machinery (China)

SHANDONG HENRY Intelligent Machinery brings fresh energy to the world of hollow block machine manufacturers, specializing in both traditional and modern brick and block making machines. Known for their versatility, HENRY offers everything from hydraulic and semi-automatic machines to fully automatic block production lines, perfect for users looking for adaptable and scalable machine solutions.

Their product range includes interlocking brick machines, paving block systems, and even soil block equipment, rounding out their offering for diverse brick making needs. What’s impressive is their clear global reach. HENRY serves markets across North and South America, Eastern Europe, Southeast Asia, Africa, the Middle East, and Western Europe, signaling solid distribution and support networks for buyers everywhere.

| Pros | Cons |

|---|---|

| ✅ From hydraulic and semi-automatic to fully automatic block-making solutions | ❌ Their broad product catalog might feel overwhelming when choosing a machine without clear specs |

| ✅ Wide geographic presence across six continents, marking strong support for global users | ❌ |

| ✅ Recognized for durable machinery and flexible block machine manufacturing options | ❌ |

Company Specifications

| Been In Business For: | Exact founding date not listed, but they're known as an experienced and established machine manufacturer in the Chinese block-making sector |

|---|---|

| Global Reach: | Active across North America, South America, Eastern Europe, Southeast Asia, Africa, the Middle East, and Western Europe |

| Technology & Certifications: | Offers hydraulic, semi-automatic, and fully automatic systems—including soil interlocking and mobile block machines |

| Production Capacity: | Covers a full range of block-making needs, from small, manual-style brick-making machines to industrial-scale automatic block-making lines |

Conclusion

Choosing the right partner from the world’s top hollow block machine manufacturers can shape the success of your next construction project. Whether you need a compact block making machine to get started or a fully automatic production line for large-scale brick production, the companies on this list have proven their reliability, durability, and global reach.

If you’re ready to explore options, Lontto is here to guide you with expert advice and dependable block machines designed to keep your business moving forward. Contact us for an obligation-free quote!

Frequently Asked Questions

What types of blocks can hollow machines produce?

Hollow block machines are versatile since most can also manufacture solid blocks, paving blocks, curbstones, and decorative elements using interchangeable molds, often without needing a different machine.

How durable are hollow block machines, and what affects their longevity?

With proper care, quality block machines can last between 15 to 25 years or more. Lifespan depends on factors like component quality, maintenance frequency, environmental conditions, and operator know-how. European-made models often boast higher durability due to robust engineering standards.

Back to Top: Top 10 Hollow Block Machine Manufacturers

I am Chao Zhang, I have been working in the brick making industry for over 10 years. I have a deep understanding and research on various models of block making machines, especially automatic brick machines, concrete block machines, compressed earth block machines, clay brick machines, cement brick machines. I have a special understanding of this industry. I can help my clients choose the suitable brick machine and assist them in designing and building a brick production factory. If you want to know everything about brick making machines, please contact me. I am happy to help you.